Mini

Mini-PFALs are closed or semiclosed indoor plant-growing systems with an air volume of plant-growing space size ranging from 3 to 30 m3, therefore suitable for several uses such as production of plants for offices, schools, shops or hospitals.

Micro-PFALs are characterized by:

- hydroponic or soilless culture;

- plants grown mostly under LED lamps;

- well-designed as small furniture or a green interior (highly attractive and safe);

- easy to use and also maintain;

- no use of pesticides;

- the lighting period, watering, temperature and other factors can be controlled both automatically or manually according to the user’s choice.

BOLOGNA

Box container farm (in collaboration with Scalabros)

The box container by Scalabros is an innovative cultivation room built in a reconditioned marine refrigerated container, used for the cultivation of mushrooms, salads, plants, microgreens.

- The container can be easily transported, thanks to its characteristics.

- Use of sensors placed in different areas of the container to control the cultivation environment and set the setup for the different cultivation stages.

- Limited energy consumption thanks to: automation and IoT, insulation, right sizing of lighting and machinery for air conditioning and humidity.

- Energy consumption is monitored continuously and can be viewed from the control panel.

- Farming on 3-4 levels to increase production.

- Possibility to select the automatic or manual control mode, allowing to automatically control all the environmental parameters according to the values set for the cultivation of a given species.

- Remote control and data collection in real time.

Box Container Farm

PADOVA

Mushrooms farm

The experimental module for the cultivation of edible mushrooms at the University of Padua is an innovative structure designed to optimize production through vertical farming and the use of differentiated lighting. The module is located at the Agripolis Campus in Legnaro (PD).

The mushroom farm, 25 m long and 8 m wide, is covered with insulating material to ensure a controlled environment.

The system consists of:

-

A cooling panel along the entire South end, powered by an underground tank with a submersible pump.

-

Two extractors on the North wall connected to the cooling system, which can also be activated independently.

-

A diesel burner suspended at the tunnel entrance, with a fan for internal air recirculation via an air sock during the summer.

The heating, cooling, and ventilation systems are controlled via an electric panel located at the entrance of the greenhouse, allowing programming or individual activation of the systems.

Humidity is maintained by a suspended fog system, consisting of misting nozzles that ensure rapid and uniform humidification.

All systems are regulated by sensors suspended in the center of the tunnel:

-

A temperature sensor communicates with the heating and cooling systems.

-

A hygrometer controls the fog system.

-

Three thermal probes inserted into the cultivation bags monitor the substrate temperature.

The structure is equipped with shelving for vertical cultivation and differentiated LED lighting systems:

-

Futura lamps (C-LED) designed to emit wavelengths in blue, red, and far-red.

-

Dimmable lamps, with light intensity adjustable from 0 to 50 µmol m⁻² s⁻¹ at the cultivation bags.

The control of environmental parameters and systems is automated, with the option for manual management.

Continuous data monitoring and remote control allow optimization of growth conditions and improvement of production efficiency.

Mushrooms farm

Tower Aquaponic Systems

The aquaponic system at the University of Padua is an innovative structure designed for the vertical cultivation of horticultural species, integrated with fish farming. The system is located at the Experimental Agricultural Farm of the University of Padua, situated at the Agripolis Campus in Legnaro (PD).

The system is easily manageable thanks to its modular configuration. Nine cultivation systems are positioned inside a tunnel greenhouse, allowing the management of three treatments with three replications each. Each system consists of:

-

A main tank of 500 L for fish farming.

-

A decanter for the deposition of solid organic residues.

-

A biofilter with plastic filtering spheres for water purification.

-

A storage tank with a booster pump that distributes water to the cultivation towers (9 per system).

-

A drainage recovery tank with a pump that returns the water to the fish tank, after thermostating through a cooling/heating unit.

Cultivation takes place on vertical towers, each capable of hosting 8 plants, for a total of 72 plants per system. This setup significantly increases crop density, achieving values up to 7 times higher than open-field cultivation, especially for leafy vegetables. The towers are fed by self-compensating irrigators calibrated according to the cultivated species.

Energy consumption is limited thanks to the automation of water flows, optimization of water distribution, and thermal control. Each system handles a total volume of 800 liters of water/nutrient solution, with a flow rate of 120 L/h, ensuring four complete recirculations per day.

Energy consumption and cultivation parameters are continuously monitored and viewable through control panels.

It is possible to select automatic or manual control modes, allowing the management of all environmental and water parameters according to the needs of different horticultural species. The system also allows remote control and real-time data collection.

Tower Aquaponic Systems

NAPOLI

Mini PFAL9.5

The University of Naples has developed the Mini PFAL 9.5, a two-tier indoor cultivation system with a total area of 0.95 m² (95 × 50 cm per shelf). This unit integrates an advanced environmental control system through an HVAC unit, which precisely regulates growth parameters. The system comprises:

- A heat pump cooling unit (800 W).

- A resistance heater (500 W).

- Tangential fans for air recirculation (50 W).

- An ultrasonic humidifier with a capacity of 200 mL/h.

- Extraction fans for air exchange.

Each shelf is illuminated by a 750 W LED panel (K5 Series XL750, Kind LED, Santa Rosa, CA, USA), emitting in the PAR range (400–700 nm) and featuring three individually dimmable channels: red (600–700 nm), blue (400–500 nm), and yellow-green (500–600 nm). The lighting system ensures a PPFD ranging from 50 to 400 µmol m⁻² s⁻¹, with homogeneous distribution on each shelf.

The Mini PFAL 9.5 is designed for microgreens cultivation in trays, with the possibility of growth both on substrate and in free-root hydroponic culture (Deep Water Culture). The integration of an automated control system allows for remote and real-time management of environmental parameters, optimizing growth conditions for different experimental configurations.

Overall, the Mini PFAL 9.5 represents an innovative and flexible solution for indoor research and production, combining precise environmental control with customizable lighting to maximize cultivation efficiency.

Mini PFAL9.5

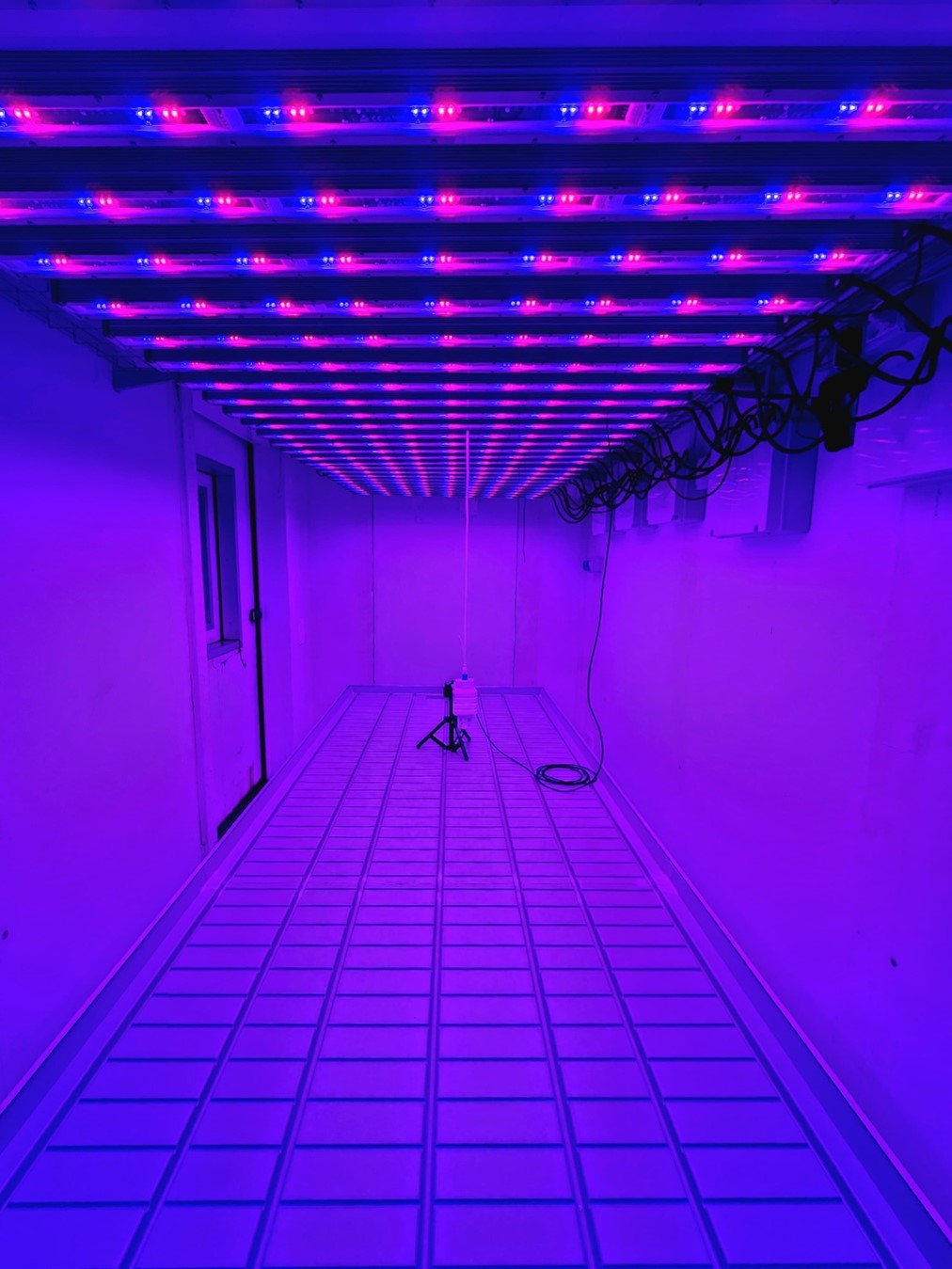

Mini PFAL16

The University of Naples has developed the Mini-PFAL16, a 16 m² (4 × 4 m) masonry structure designed for indoor hydroponic cultivation. The interior walls are coated with white resin, impermeable to liquids and gases, ensuring a controlled and easily sanitized environment. The cultivation system comprises two aluminum benches with Danish trays (120 × 300 cm), equipped with an ebb and flow system that allows for closed-loop hydroponic cycle management. This configuration optimizes the use of water and nutrients, ensuring efficient crop management.

Nutrient management is handled by independent fertigation units (NIDO ONE V2), remotely controllable via PC or mobile app. Each system is equipped with sensors for measuring electrical conductivity (EC) and pH, as well as four peristaltic pumps for the automatic dosing of acids, bases, and concentrated nutrient solutions. This setup ensures precise and efficient nutrient solution management, adaptable to the specific needs of the crops.

The HVAC system of the Mini-PFAL16 is designed to precisely regulate the environmental parameters of the cultivation chamber and includes:

- A heat pump cooling unit (1200 W).

- A resistance heater (2000 W).

- Axial fans for air recirculation (450 W).

- Two ultrasonic humidifiers with a capacity of 1 L/h each.

- Two extraction fans for air exchange (50 W each).

The Mini-PFAL16 represents a technologically advanced solution for indoor hydroponic research and production. The integration of precise environmental control and an automated fertigation system allows for the optimization of growth conditions, offering a highly efficient infrastructure adaptable to various experimental needs.

Mini PFAL16