Ergonomics and Human-Centered Design

We work on making industrial products and processes more comfortable, efficient, and human-friendly.

Our activities mainly focus on:

1. Studying How People Work and Interact: we conduct studies to understand how real people use products and machines in industrial settings. We observe, ask questions, and run experiments to figure out what works, what’s frustrating, and how things could be better.

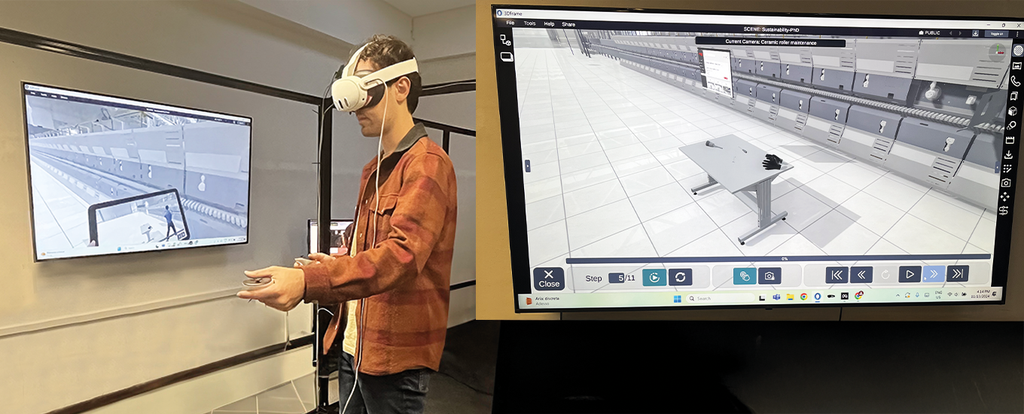

2. Optimizing Workplaces for Comfort, Safety and Sustainability: we analyze workstations, tools, and workflows to make sure they’re ergonomically sound, reducing physical and cognitive stress on the body and making tasks easier. We use digital simulation and VR immersive environments to test and validate the workplace layout and working tasks, promoting users' well-being and sustainable practices.

3. Using VR and AR for Designing and Training: we use advanced technolgies as virtual and augmented reality to simulate factory floors, workstations, and interactions in general before anything is built. This helps us fine-tune designs and train workers in safe, controlled environments.

4. Studying Cognitive Load and Human Performance: we measure human workloads by assessing users' stress, and fatigue to make sure tasks are manageable and efficient, reducing errors and burnout.

5. Design for ALL: we work on making products and processes that are accessible and easy to use for as many people as possible. We stay on top of industry standards, safety rules, and ergonomic guidelines, helping companies comply with regulations while still keeping things practical and worker-friendly.