Digital Simulation and Optimization

We leverage cutting-edge simulation technologies to predict system behavior, accelerate design cycles, and reduce development costs—while enhancing accuracy and decision-making.

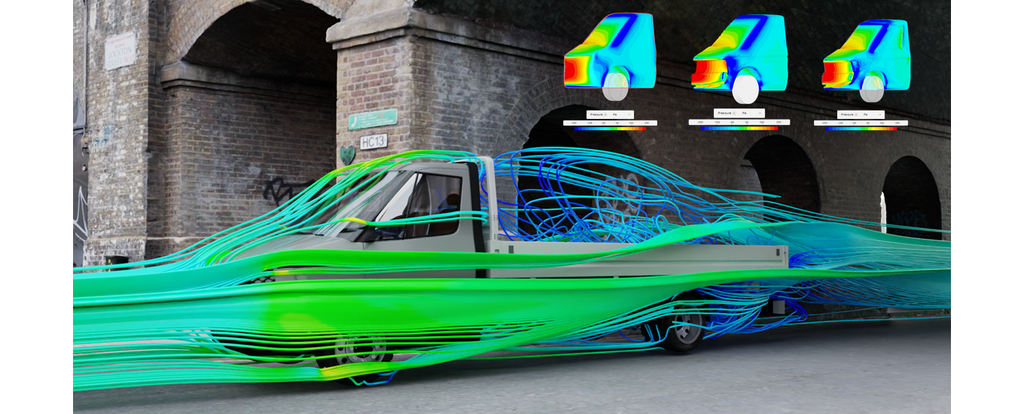

- Interactive Aerodynamic Assessment in Vehicle Design: We create integrated workflows that connect vehicle styling and aerodynamic analysis through real-time visualization tools, using fast-response CFD visualization embedded in computer graphics environments. This approach reduces iteration cycles and enhances early aerodynamic performance validation during vehicle body design.

- ANOVA – DOE – RSM applications: Analysis of variance (ANOVA) is often applied to case sensitive studies (DOE) carried out on schematizations of whole models of vehicles to derive response surfaces (RSMs) representative of their behaviors. The ultimate goal is to: Identify design inconsistencies early on, anticipate the identification of optimal architectural setups/configurations and start CAD modeling phases already knowing optimal geometries and parameters.

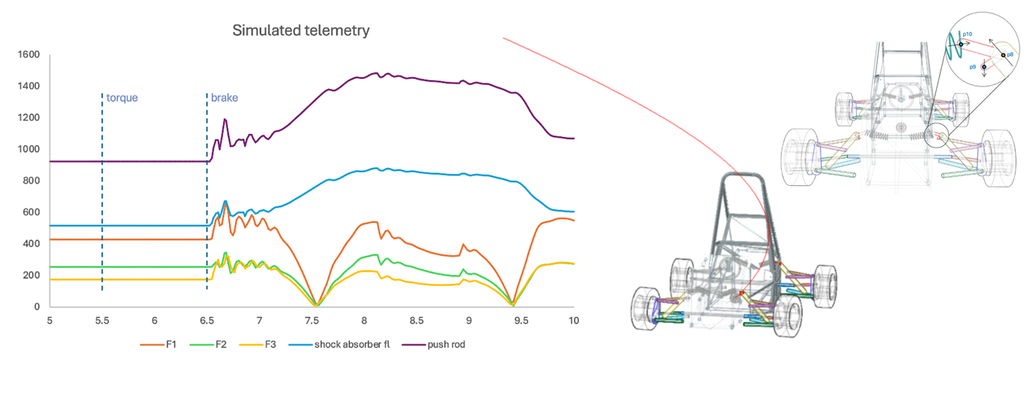

- Neural Networks applications: Neural network models are similarly applied to the vehicle to identify optimal product configurations, simulate and predict the behavior of nonlinear models and define the vehicle architecture based on specific technical requirements. NNs are also applied to live time simulations (vehicle simulator) together with ML and DL suites useful to improve the driver skills during his training on a circuit/use of the virtual mockup of the vehicle.

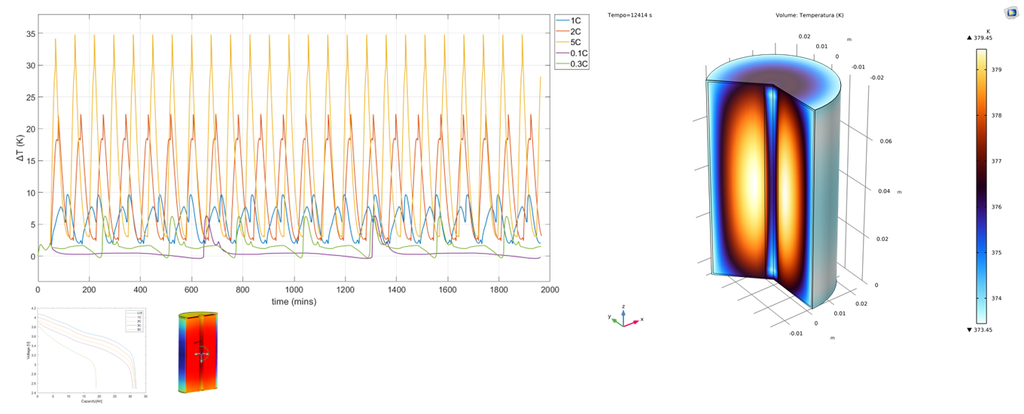

- Multiphysics Simulations of Lithium-Ion Cells: Advanced multiphysics simulation models are developed and applied to predict the thermo-electrochemical behavior of lithium-ion battery cells under various operating conditions. This enables optimization of cell design, enhances safety assessment, and supports the development of efficient thermal management strategies for next-generation energy storage systems.

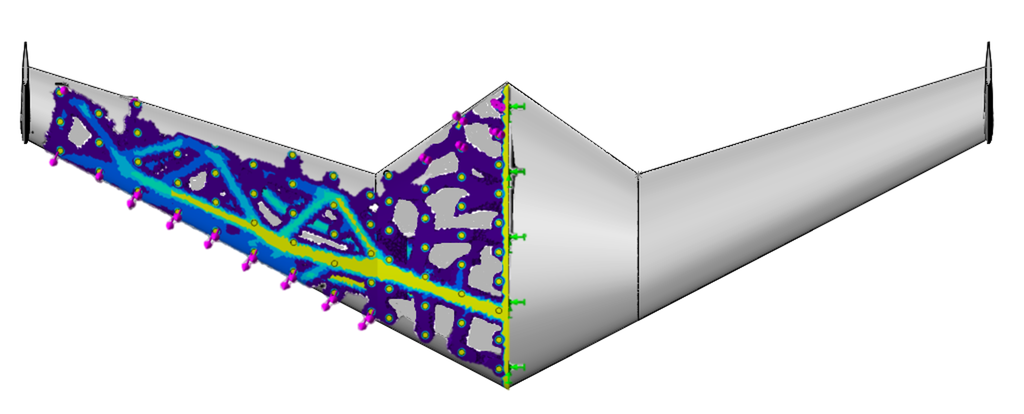

- Topology optimization for aerospace structures: Advanced topology optimization strategies to design lightweight, efficient, and manufacturable structures for dynamic and complex engineering applications. Key activities include AI-driven frameworks to automate parameter tuning in frequency-based structural optimization, ensure structural connectivity and manufacturability in complex 3D domains, enabling robust solutions for additive manufacturing. Additionally, an enhanced vertex-based surface smoothing algorithm is developed to improve the manufacturability of topology-optimized components.

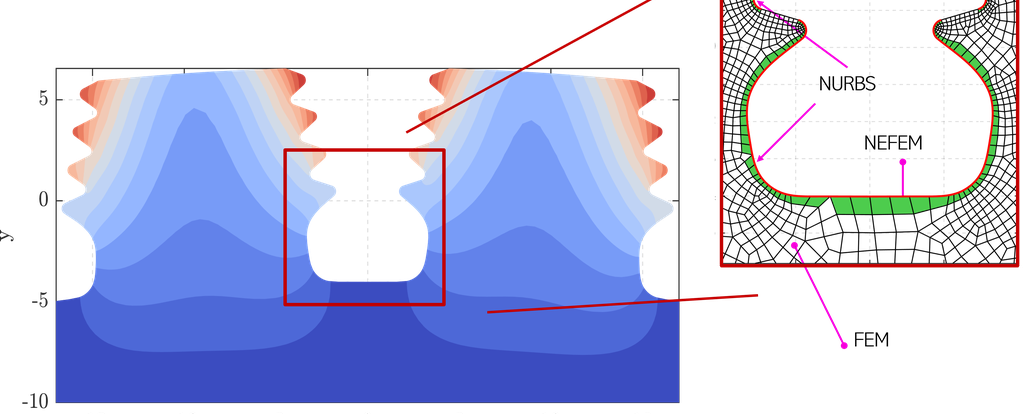

- NEFEM for the Simulation of Complex Geometries: Development and application of the four nodes NEFEM (NURBS-Enhanced Finite Element Method) for high-fidelity simulation of two-dimensional domains with complex geometries. Key activities include the direct integration of CAD-based NURBS representations to enhance boundary accuracy, and reduce geometric errors typical of standard FEM. This approach enables more robust and reliable analysis, especially in scenarios where adherence to the exact geometry is critical to the quality of the results.