3DPLab

Advancing additive manufacturing through 3D printing innovation, optimizing processes and materials to produce complex, customized components for industrial applications.

Activities

-

Surface Optimization for High-Performance Tribological Applications

3D-printed surfaces are refined to improve their performance under friction-intensive conditions, essential in tribological systems. Techniques are applied to reduce surface roughness, increase uniformity, and enhance material behavior during contact and movement. These optimizations contribute to longer part lifespans, lower energy consumption, and improved reliability in mechanical assemblies. The process is ideal for components subjected to continuous motion or mechanical stress.

-

Advanced Prototyping of Custom Components through Laminated 3D Printing

Custom components are developed using advanced lamination techniques applied to 3D-printed parts. This approach enables the creation of lightweight yet robust elements, suitable for structural applications. The process allows for rapid iterations, material versatility, and the production of complex geometries tailored to specific project requirements. It is particularly valuable in early-stage product development and functional testing. Laminated prototypes serve as a reliable bridge between conceptual design and final production.

-

Ergonomic Validation through Automotive Seat Prototyping

A full-scale automotive seat is produced to facilitate detailed ergonomic studies and assess user comfort in realistic conditions. This prototype enables thorough human-vehicle interaction analysis, providing key insights into posture, reach, visibility, and usability. The process supports design refinement and enhances safety and comfort from the earliest development stages. Such testing is essential for aligning industrial design with ergonomic standards and regulatory compliance.

-

Collaborative Workflow for Large-Scale 3D Printing Optimization

High-volume 3D printing is enhanced through collaborative workflows that streamline production, reduce downtime, and improve overall efficiency. By coordinating across machines and teams, complex production goals can be met with consistency and scalability. This approach is ideal for industrial environments requiring rapid manufacturing of multiple custom parts. It also facilitates quality control, workflow tracking, and flexible job management across shared platforms.

-

Functional Prototyping for Automotive and Motorcycle Components

Functional parts are produced for integration into automotive and motorcycle systems, focusing on real-world performance and reliability. These components are designed to meet stringent mechanical and dimensional requirements, often serving as working prototypes or end-use parts. The process allows for customization, material testing, and compatibility checks within existing assemblies. It supports faster product validation and reduces development time for mobility solutions.

-

Rapid Mock-Up Production for Style Verification and Full-Scale Body Modeling

Quick mock-up fabrication is used to validate aesthetic and design choices through the production of individual components or complete vehicle bodies. This process enables real-time assessment of proportions, volumes, and stylistic coherence before committing to costly tooling or production. It serves as a critical step in the design cycle, allowing designers and engineers to refine surfaces, integrate feedback, and align with brand identity. Full-scale models enhance communication between design teams and stakeholders, accelerating decision-making and reducing development times.

Projects

-

AM3-CIRCULAR

AM3-CIRCULAR is an innovation project aimed at developing a prototype system for assessing environmental sustainability by leveraging the potential of Additive Manufacturing (AM). Integrating Life Cycle Assessment (LCA), Life Cycle Costing (LCC), and material circularity, the project promotes resource efficiency, waste reduction, and minimized environmental impact—specifically within the motorcycle and biomedical sectors. The approach combines the flexibility of on-demand production with the principles of ecodesign, maximizing both environmental and economic benefits. AM3-CIRCULAR proposes a forward-looking industrial strategy that responds to growing consumer demands while offering long-term competitive advantages for companies embracing sustainable manufacturing.

-

GOALS

Green Optimizations by Additive-manufactured Lightweight Structures

-

SPACELAB

Design, manufacturing, and validation of test benches for strategic and advanced environmental tests for the aerospace sector

Equipment

-

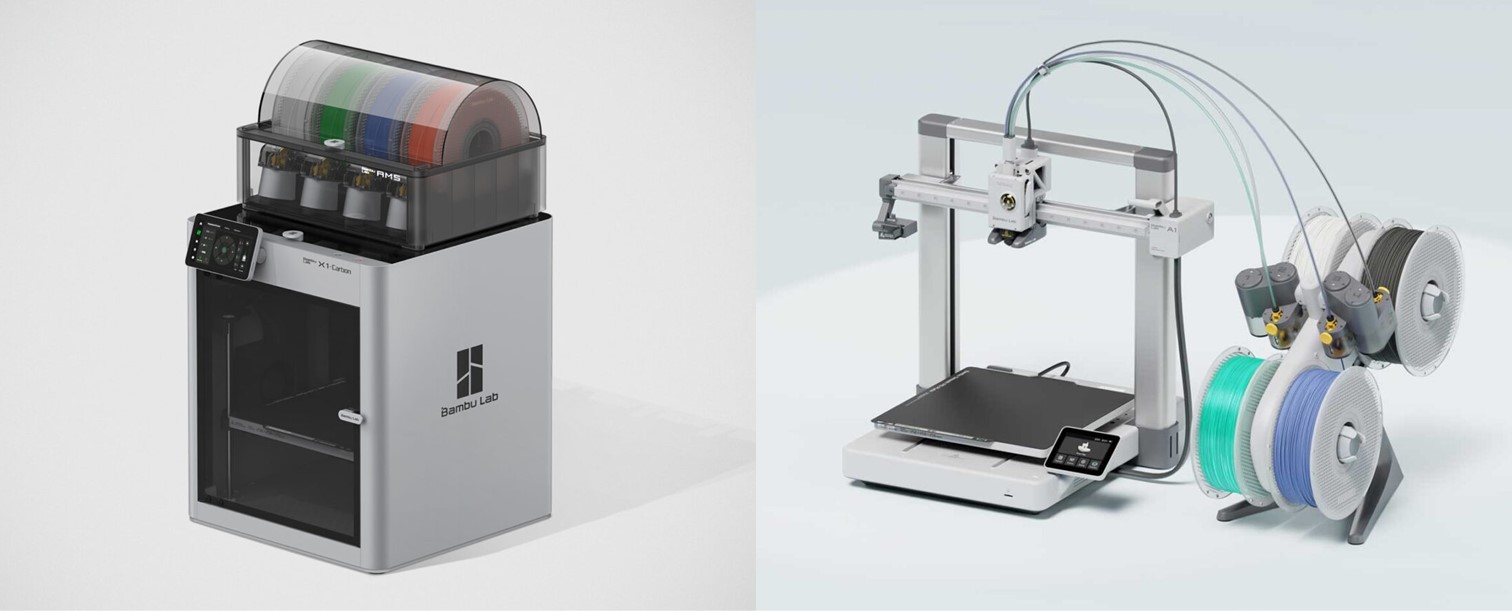

Bambu Lab X1 Carbon

A high-speed FDM 3D printer equipped with a hardened nozzle and advanced cooling system, enabling reliable printing with engineering-grade materials like carbon fiber and glass fiber composites. It supports multi-material and multi-color printing via the AMS system, making it ideal for rapid prototyping and functional parts.

-

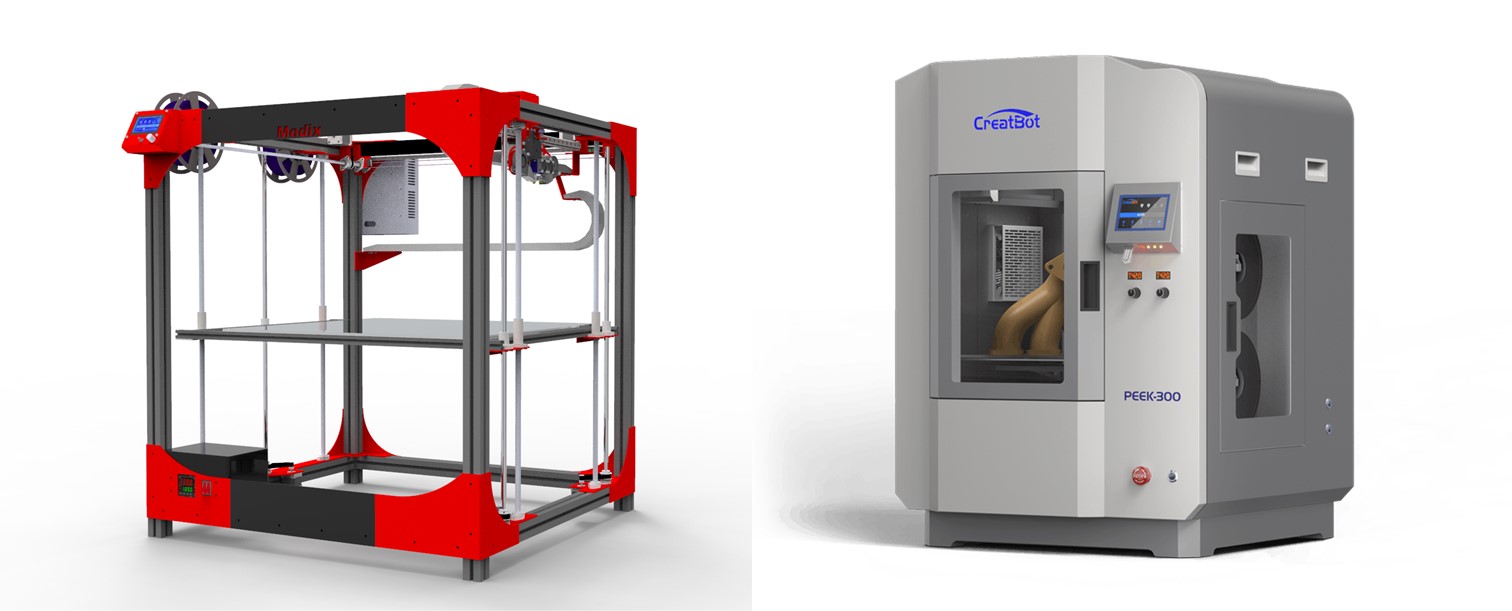

Creatbot PEEK-300

An industrial-grade 3D printer designed for high-performance polymers such as PEEK and ULTEM. It features dual nozzles capable of reaching up to 480°C, a heated bed up to 200°C, and a fully enclosed heated chamber up to 120°C, ensuring dimensional stability and strength in printed parts.

-

E3D ToolChanger

A modular 3D printing system that allows automatic swapping between up to four toolheads, enabling multi-material and multi-process printing. Its open-source design and high-temperature capabilities (up to 500°C) make it suitable for research and advanced prototyping.

-

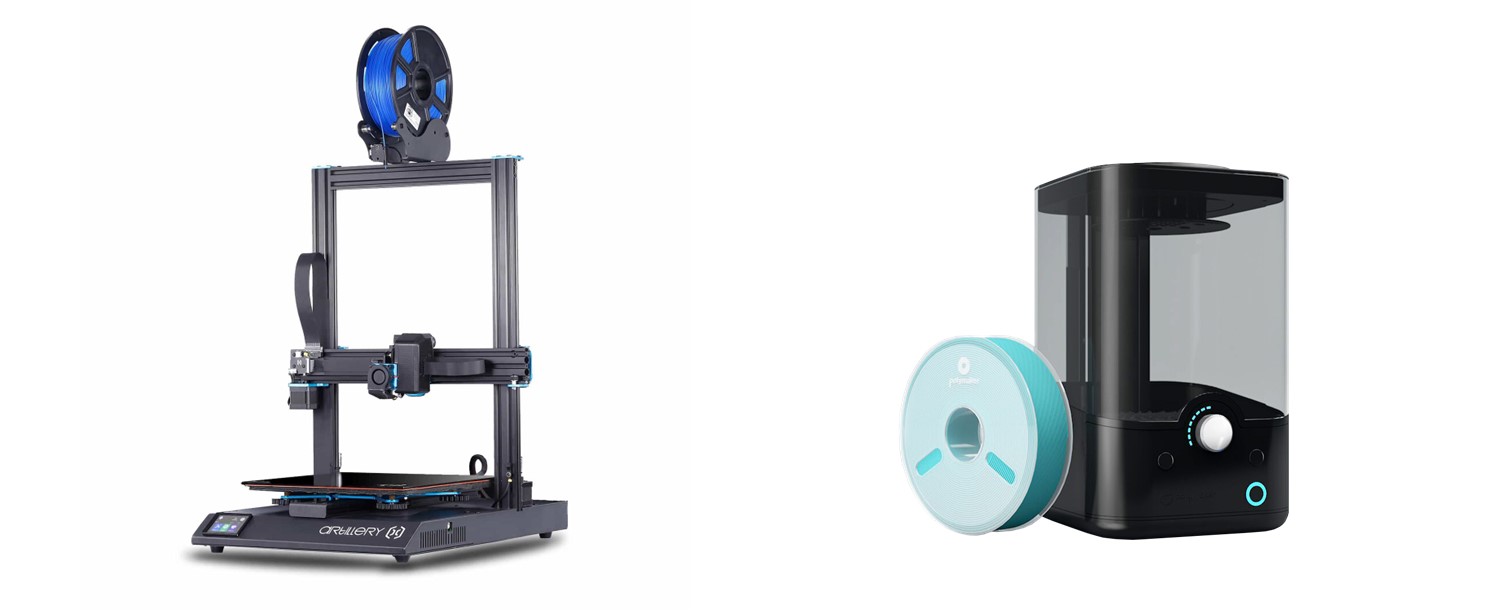

Artillery Sidewinder X2

An upgraded version of the X1, this printer includes automatic bed leveling, a 32-bit motherboard with silent drivers, and improved filament run-out detection. It maintains the same large build volume and is designed for enhanced reliability and ease of use.

-

Anycubic Photon M3 Max

A resin-based 3D printer featuring a 13.6-inch 7K monochrome LCD screen, providing high-resolution prints with a build volume of 300 x 298 x 164 mm. Its matrix light source and smart resin filling system make it suitable for detailed models and large-scale resin printing.

-

Bambulab A1

A high-performance desktop FDM 3D printer designed for precision, speed, and ease of use. With its intuitive interface and advanced motion control system, the A1 delivers reliable prints across a wide range of materials, including PLA, PETG, TPU, and more. Ideal for prototyping, functional parts, and educational use, the A1 combines professional-grade results with a user-friendly experience.

-

Intamsys Funmat HT

An industrial-grade FDM 3D printer engineered for high-performance materials. It supports a wide range of advanced thermoplastics, including PEEK, PEI (ULTEM™), and PPSU, thanks to its high-temperature capabilities: a 450 °C extruder, 160 °C heated bed, and 90 °C enclosed chamber. An ideal solution for functional prototyping, tooling, and end-use parts in aerospace, automotive, and medical industries.

-

Modix Big60v2

A large-format, modular FDM 3D printer designed for professional and industrial applications. It features a generous build volume of 600 × 600 × 660 mm, enabling the production of large prototypes, functional parts, and assemblies in a single print.

-

Formlabs Form 2

A professional-grade desktop stereolithography (SLA) 3D printer renowned for its precision and reliability. It offers a build volume of 145 × 145 × 175 mm and supports layer resolutions of 25, 50, and 100 microns, making it ideal for producing detailed prototypes and functional parts.

-

Anycubic Wash & Cure

A dual-function machine that streamlines the post-processing of resin prints by offering both washing and UV curing in a single device. It features a 360° rotating platform and adjustable curing times, ensuring thorough and efficient post-processing.

-

Polymaker Polysher

A desktop post-processing unit designed to remove layer lines from PolySmooth™ and PolyCast™ 3D printed parts. It uses Polymaker’s Layer-Free™ technology to create a fine mist of alcohol, evenly smoothing the model's surface for a glossy finish.

-

Formlabs Form Cure

A professional-grade post-curing chamber designed to enhance the mechanical properties and performance of SLA 3D printed parts. By precisely combining 405 nm UV light with controlled heat, it ensures optimal polymer cross-linking, resulting in improved strength, durability, and thermal stability.

Equipment overview