3D Printing

It centers on the advancement, assessment, and refinement of 3D printing technologies aimed at enhancing additive manufacturing processes across various industrial domains. This multidisciplinary area brings together concepts from materials science, mechanical engineering, digital fabrication, computer-aided design (CAD), and process optimization to enable precise, customizable, and efficient production of complex components through layer-by-layer material deposition.

Research activities include:

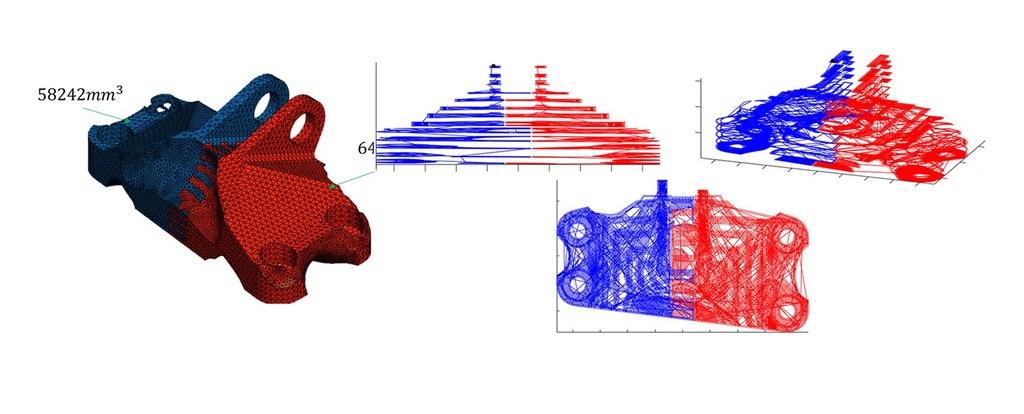

- Geometric and dimensional analysis using advanced tools for the verification of complex components to ensure accuracy and compliance with design specifications.

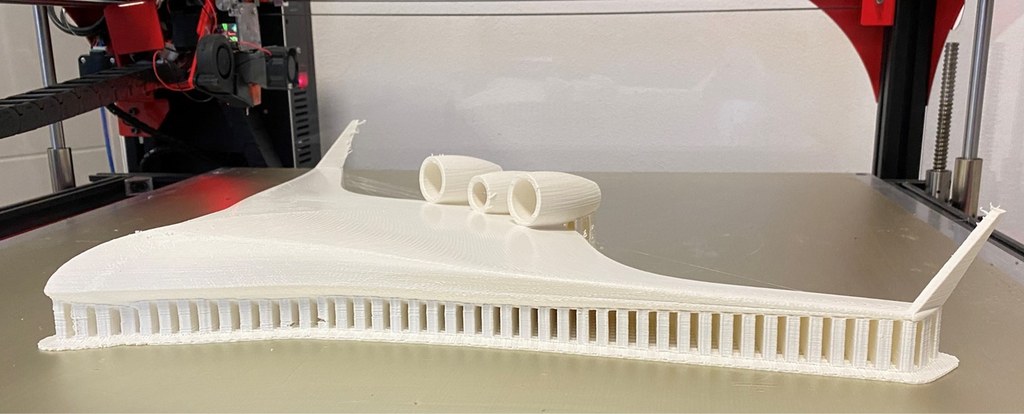

- Surface finish optimization of parts produced through Fused Filament Fabrication (FFF), with a focus on minimizing the staircase effect on curved surfaces.

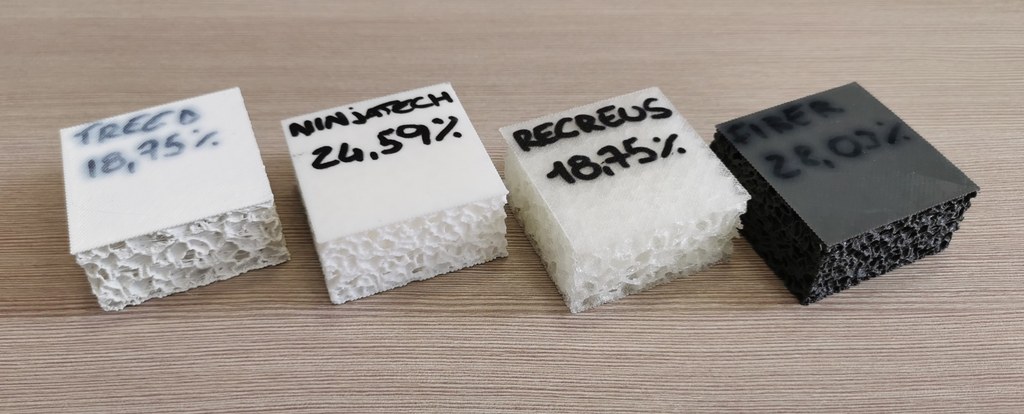

- Sustainability assessments and metal replacement strategies aimed at converting functional components into high-performance polymeric alternatives for improved industrial and environmental efficiency.

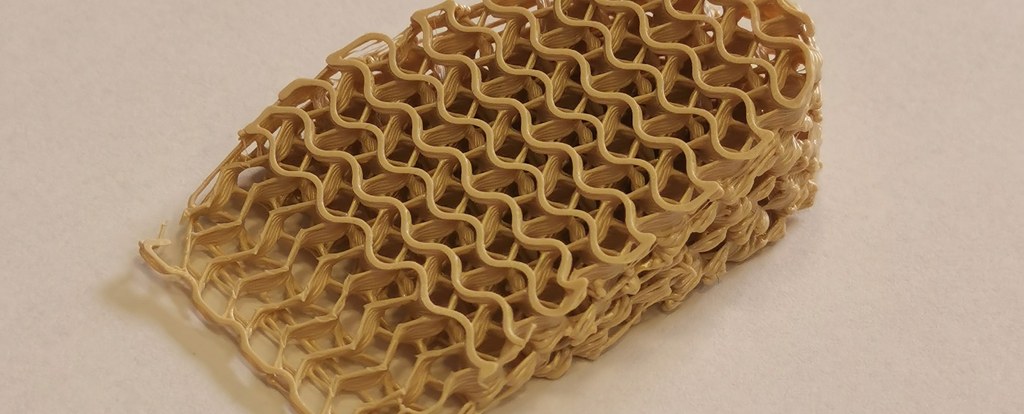

- Development of alternative deposition strategies to enhance the quality, repeatability, and overall efficiency of the 3D printing process.

- Development of toolpath planning strategies for collaborative large-scale Material Extrusion machines