Cyber-Physical Simulation

We focus on simulating, visualizing and controlling complex industrial systems by tightly integrating digital and physical environments. Our goal is to create accurate digital counterparts of real machines (digital twins) that enable predictive analysis, immersive planning and remote collaboration.

Our activities mainly focus on:

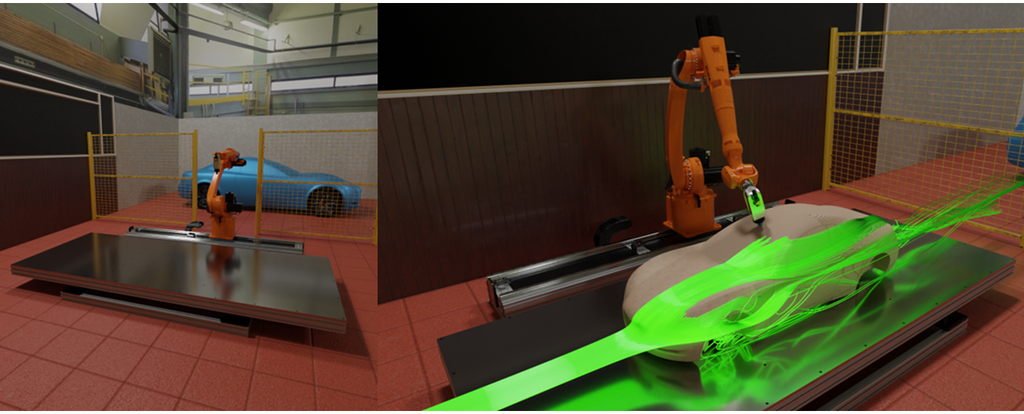

- High-Fidelity Simulation of Real-World Systems: Developing methodologies to replicate the behavior of physical systems in real time, ensuring a reliable correspondence between virtual representations and actual machines. These simulations allow for risk-free experimentation, predictive maintenance and layout validation.

- Augmented Visualization of Incomplete or Evolving Prototypes: Using extended reality to digitally complete physical mock-ups, such as partially milled vehicle maquettes, enabling real-time visualization of the final shape, material finishes and color variants before the physical model is complete.

- Motion Tracking and Digital Twin Synchronization: Integrating motion capture systems like OptiTrack to track and replicate the behavior of robotic systems. This allows us to monitor, simulate and remotely control machinery with precision, bridging physical operations and digital environments through actuated interfaces.

- Collaborative Industrial Workspaces in XR: Enabling remote design reviews, multi-user planning and immersive evaluation of industrial setups by creating shared XR environments. These collaborative platforms enhance communication across geographically distributed teams and support decision-making with real-scale, data-rich simulations.