R3PACK

R3PACK is a Horizon Europe 2022–2025 project that aims to replace plastic with fiber in food packaging and promote large-scale reusable packaging systems across Europe.

R3PACK: REDUCE, REUSE, RETHINK PACKAGING

What is R3PACK? A short introduction to the project.

The MISSION of R3PACK and the Contribution of the FSC Center

R3PACK is a Horizon Europe project that aims to transform the packaging sector towards sustainability, contributing to the Green Deal targets: climate neutrality by 2050 and 100% reusable or recyclable packaging by 2030. From 2022 to 2025, 24 partners are working to accelerate the adoption of innovative and cost-effective technologies, replacing multilayer plastics with fiber-based materials, while complementing this transition with optimized, large-scale tested reuse systems.

Within the project, the FSC Center contributes to the development and optimization of reuse systems, with a specific focus on logistics modeling. Prof. Riccardo Accorsi leads Work Package 3: REUSE: towards industrial, economic and environmental optimisation. Together with his research team, he designs and analyzes efficient network configurations for the collection, transport, and reuse of packaging, considering economic, environmental, and operational criteria. Special attention is devoted to uncertainty management, exploring how it may affect overall system performance. The ultimate goal is to identify the most effective solutions to enable large-scale, sustainable, and resilient reuse.

How are the challenges of implementing a reusable packaging system in Europe addressed in R3PACK?

In this video, (RE)SET President Antoine Covillers explains how the R3PACK consortium will approach the study and field testing of reusable packaging.

The reuse logistics: the invisible engine of sustainable packaging

Rethinking Packaging: why reuse is a logistic challenge

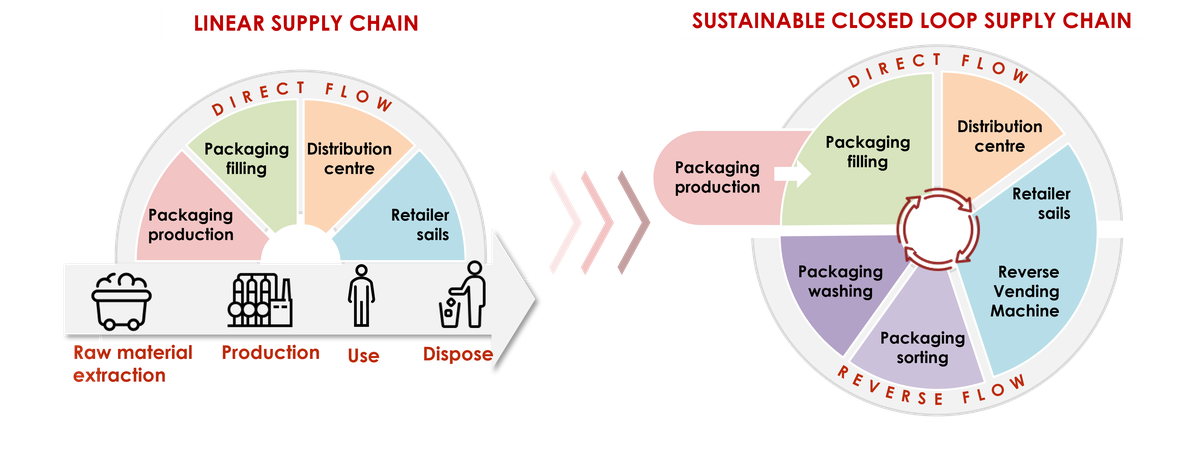

Single-use packaging, especially plastic, is one of the main environmental challenges in the food sector. Transitioning to reusable packaging systems offers a promising solution, though not without complexity. Behind every reusable container lies a network of operations involving production, distribution, collection, washing, and reintroduction to the market.

To make reuse truly sustainable, it is essential to design efficient and resilient logistics networks capable of balancing economic costs and environmental impacts. The FSC Center is committed to modeling and optimizing these networks, exploring how to improve each link in the reuse chain.

Who are the actors of reuse, and what factors shape an efficient system?

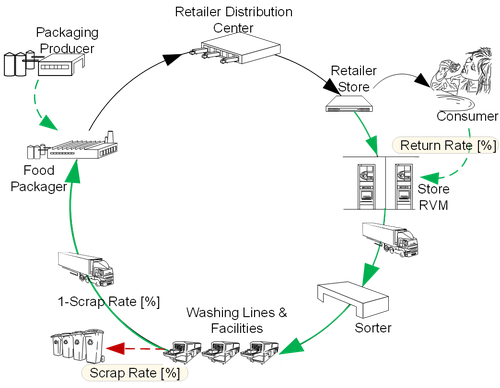

An effective packaging reuse system relies on the coordinated effort of many different actors, each with a crucial role. Packaging producers must design durable containers capable of withstanding multiple cycles of use. Food producers need to adapt their production lines to handle reusable packaging, which is often heavier or bulkier than single-use alternatives. Distribution centers and retailers act not only as delivery points but also as hubs for collecting used packaging. Consumers, returning the used packaging, ultimately determine the system’s success: without their active participation, the loop breaks.

To close the loop, sorting and washing facilities ensure hygiene and quality, while logistics operators connect all these stages, managing the transport of packaging across the network. In system modelling, each of these categories of actors is represented with its own constraints, costs, and responsibilities. Only by considering their interdependencies can a truly functional and resilient reuse network be designed.

Yet reuse is not only about producing less packaging, it also requires managing more complex logistics flows. Every reusable container must be collected, washed, and redistributed, which introduces additional costs and environmental impacts that must be carefully balanced. Evidence from the R3PACK project shows that the efficiency of reuse systems depends on factors such as container durability and consumer willingness to return them. The more reuse cycles a container completes, the greater its environmental benefit.

At the same time, the strategic location of facilities can reduce both logistics costs and emissions, reinforcing the sustainability of the system. Mathematical optimisation models help simulate different scenarios, allowing researchers and practitioners to identify the most effective network configurations.

Ultimately, only by integrating analytical tools, logistics design, and collective behavior can packaging reuse evolve into a systemic and sustainable alternative to single-use solutions.

INSIGHTS

-

Rethinking packaging: how optimization models support the design and management of sustainable reusable packaging networks

What lies behind a truly effective reusable packaging system? In this feature article, we explore how mathematics and logistics work together to make reusable packaging possible, sustainable… and cost-effective.

DELIVERABLES

-

This document presents how to configure the reusable packaging network in a sustainable way, both environmentally and economically. Using a location-allocation model developed by the FSC Center team at UniBo, the entire closed-loop logistics network is analyzed, identifying the optimal location of facilities and the allocation of flows. The model compares different packaging types, previously designed and tested, by integrating environmental data as well as consumer behaviors and preferences. Optimization is carried out through mixed-integer linear programming (MILP), and the resulting outcomes (optimal packaging, reuse strategies, and logistics configurations) feed into field validation phases and the commercialization of alternative reusable packaging solutions.

Project partners

Coordinators, Retailers, Industrial Partners, Experts and Enabling Partners

OFFICIAL WEB SITES

-

R3PACK Website: REDUCE, REUSE, RETHINK PACKAGING

Visit the R3PACK website to explore updates and deliverables from a European initiative that brings together industry and academic partners to shape the future of packaging.

-

European Project Website

Project information and results

Project scientific output

List of publications related to R3PACK

-

Reusable food primary packaging in retail supply chain: A multi-objective optimization framework

Sustainable Production and Consumption, 2025

-

Data architecture framework for reverse logistics management in reusable food packaging networks

Procedia Computer Science, 2025

This project has received funding from the European Union’s Horizon Europe research and innovation programme under Grant Agreement No. 101060806.