Publications

An optimization framework for energy-driven food cold chain network design, 2025

Elsevier International Journal: website

Authors: Riccardo Accorsi (a), Emilio Ferrari (a), Beatrice Guidani (a), Riccardo Manzini (a), Michele Ronzoni (a)

(a) Department of Industrial Engineering, Alma Mater Studiorum – University of Bologna, Italy

Abstract

Cold Food Supply Chains (CFSCs) are crucial for sourcing, consolidating, and delivering fresh food from suppliers to consumers. However, they also account for up to 35 % of the food industry’s energy consumption. This study introduces an optimization framework aimed at strategically designing more energy-efficient cold chain networks. It takes into consideration the impact of site-specific climate and irradiance conditions on refrigeration energy consumption in warehouse facilities, along with logistical considerations. The framework incorporates a Mixed-Integer Linear Programming (MILP) model for energy-focused cold chain facility network design. A case study, applied to a nationwide fresh fruit retailer supply chain in Italy, highlights the practical benefits of this approach. Results demonstrate that by strategically locating refrigerated warehouses in areas naturally shielded by mountain reliefs, the model achieves a 23 % reduction in energy consumption and a 5 % total cost saving compared to a business-as-usual scenario. These findings underline the importance of integrating environmental parameters, such as climatic and irradiance conditions, into cold chain network design to enhance energy efficiency and sustainability while maintaining logistical feasibility.

Reusable food primary packaging in retail supply chain: A multi-objective optimization framework, 2025

Elsevier International Journal: website

Authors: Riccardo Accorsi (a,b) , Giorgia Bartolotti (a), Beatrice Guidani (a), Riccardo Manzini (a), Michele Ronzoni (a)

(a) Department of Industrial Engineering, Alma Mater Studiorum – University of Bologna, Italy

(b) CIRI – AGRO, Interdepartmental Center for Agricultural Industrial Research of the University of Bologna, Via Quinto Bucci 336, 47521 Cesena, FC, Italy

Abstract

The increasing demand for sustainable and equitable raw material utilization underscores the potential of reusable packaging as an effective solution. The food retail sector, a significant contributor to packaging waste, faces a clear need for comprehensive decision support systems to manage the complexities of reusable packaging circular networks. Managing these networks requires balancing environmental efficiency with economic viability, considering enabling conditions like consumer return attitude, packaging design properties (weight, size, and stackability), and players' logistic proximity. This paper presents a multi-stage and multi-objective optimization framework designed to select optimal product-package combinations and establish a circular network that encourages the adoption of reusable food packaging in retail. The framework is applied to a significant real-world application consisting of two nationwide retailers in France. The findings confirm that high return rates (>60–70 %) are essential for the viability of the circular system whilst ensuring low scrap rates (<15 %) tip the balance for environmental benefits. Lightweight and stackable packaging solutions enhance resilience in systems with uncertain return and scrap rates. Packaging properties must be evaluated alongside logistics network configuration, as packaging selection is tied to production sites, shaping network adaptability. We introduce a new metric that evaluates packaging and network suitability by assessing packaging weight and transportation distances. A lower value indicates improved resilience and supports the long-term viability of the system. The results emphasize the role of Reusable Vending Machines (RVMs) in reducing environmental burdens, as a higher number of installations leads to greater impact reductions. However, RVM costs account for 70–87 % of differential expenses, depending on deployment scale and budget constraints. To address this, we propose a RVM allocation strategy that optimizes distribution while balancing economic and environmental trade-offs. This multi-objective optimization framework provides valuable insights for policymakers and businesses striving to scale reusable food packaging initiatives effectively

Monte Carlo-based instance generator for agri-food supply chain operations assessment, 2025

Elsevier International Journal: website

Authors: Beatrice Guidani (a), Riccardo Accorsi (a,b), Riccardo Manzini (a), Michele Ronzoni (a)

(a) Department of Industrial Engineering, Alma Mater Studiorum - University of Bologna, Viale del Risorgimento 2, Bologna, 40136, Italy

(b) CIRI –AGRO, Interdepartmental Center for Industrial Research of the University of Bologna, Via Quinto Bucci 336, 47521 Cesena, FC, Italy

Abstract

Addressing sustainability challenges within the Agri-Food system is pivotal to meeting global food demand without endangering the resilience of ecological systems. However, the complexity of Agri-Food Supply Chain (AFSC) operations and the scarcity and heterogeneity of primary data present significant obstacles to effective management. To tackle such issues, this paper illustrates a novel Agri-food supply chain Monte Carlo-based Istance GeneratOr tool (AMIGO). This tool exploits aggregated demand data and geospatial information on supply chain nodes to generate order release scheduling and realistic distribution pathways according to logistical feasibility. AMIGO design and implementation are outlined, highlighting its key components and operational principles. A case study is presented as a validation testbed. This tool is applied to generate two scenario instances for horticultural products within AFSCs. By varying supply chain features, settings, and configurations, this tool captures the nuanced dynamics of different supply chain configurations. Enabling empirical analysis, AMIGO effectively provides valuable insights into supply chain management and decision-making. Overall, it aids agri-food industry stakeholders, supports policy-making efforts and fosters innovation in AFSC management.

Data architecture framework for reverse logistics management in reusable food packaging networks, 2025

Elsevier International Journal: website

Authors: Giorgia Bartolotti (a), Beatrice Guidani (a), Michele Ronzoni (a), Riccardo Manzini (a), Riccardo Accorsi (a,b)

(a) Department of Industrial Engineering, Alma Mater Studiorum - University of Bologna, Viale del Risorgimento 2, Bologna, 40136, Italy

(b) CIRI –AGRO, Interdepartmental Center for Industrial Research of the University of Bologna, Via Quinto Bucci 336, 47521 Cesena, FC, Italy

Abstract

Managing agri-food supply chains requires the concurrent consideration of raw food and packaging materials flows. Unfortunately, packaging contributes to waste generation despite its vital role in ensuring safe distribution. To tackle this issue, the European Union fosters the adoption of reusable primary packaging and the introduction of sustainable closed-loop systems over the traditional based on single-use. Creating closed-loop packaging systems is achievable only through collaborative relationships among actors, stakeholders, and policymakers. Tailored data architectures facilitate the efficiency of such partnerships and collaboration, encouraging the adoption of sustainable paradigms. This paper proposes a data architecture framework that supports high-quality primary data collection for reusable primary packaging supply chains. Furthermore, the data framework aids decision-making processes within circular primary packaging systems, providing economic and environmental metrics. A flexible user interface facilitates the creation of customized output that impels the adoption of sustainability paradigms within the agri-food sector.

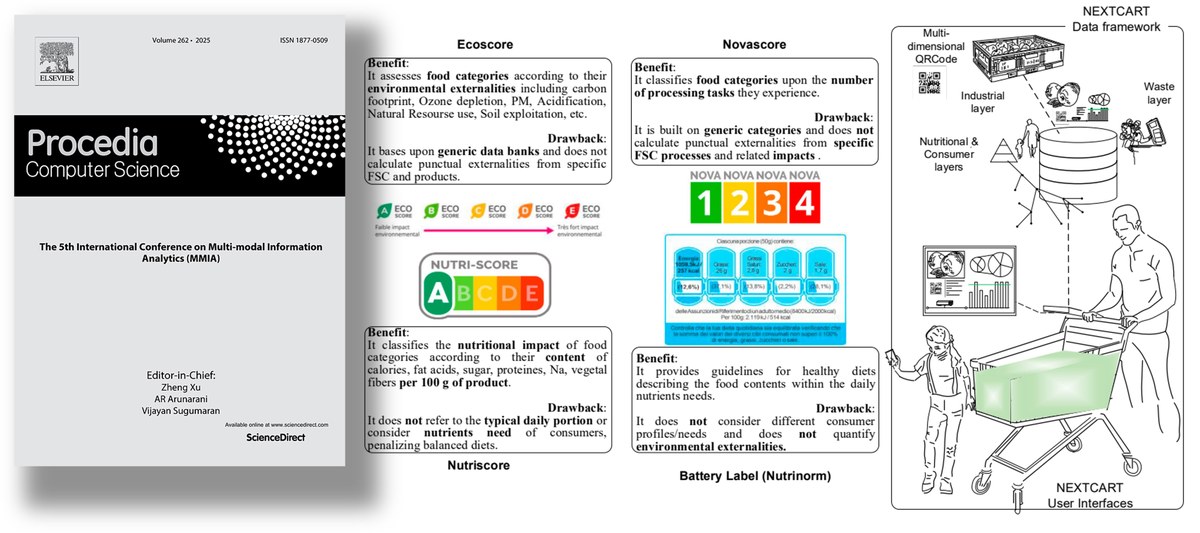

Data architecture framework for improving consumer awareness in food shopping experience, 2025

Elsevier International Journal: website

Authors: Riccardo Accorsi (a,b), Barbara Ballotta (f), Giorgia Bartolotti (a), Luca Falasconi (e), Beatrice Guidani (a), Riccardo Manzini (a), Maria Letizia Petroni (f), Michele Ronzoni (a), Anisa Rula (c), Andrea Segrè (e), Simone Zanoni (d)

(a) Department of Industrial Engineering, Alma Mater Studiorum - University of Bologna, Viale del Risorgimento 2, Bologna, 40136, Italy

(b) CIRI –AGRO, Interdepartmental Center for Industrial Research of the University of Bologna, Via Quinto Bucci 336, 47521 Cesena, FC, Italy

(c) Department of Information Engineering, University of Brescia, via Branze 38, Brescia, 25123, Italy

(d) Department of Civil, Environmental, Architectural Engineering and Mathematics, University of Brescia, via Branze 43, Brescia, 25121, Italy

(e) Department of Agricultural and Food Sciences, Alma Mater Studiorum - University of Bologna, Viale Giuseppe Fanin 40, Bologna, 40127, Italy

(f) Department of Medical and Surgical Sciences, Alma Mater Studiorum - University of Bologna, Via Massarenti 9, Bologna, 40127, Italy

Abstract

Nowadays, consumers are often influenced by retailers who prioritize economic objectives over the well-being of individuals and society. To address this issue, there is a need for tools that can help consumers make more informed and sustainable purchasing choices. This paper proposes a data architecture framework that can enable consumers to have a more aware and sustainable purchasing experience, particularly regarding food choices. The framework empowers consumers’ experience by providing access to integrated enabling technologies that promote sustainable, nutritionally complete, customized purchase choices and eating habits. Under the NEXTCART project’s framework, this paper aims to provide technological solutions that can help optimize and digitize the food supply chain, making it more environmentally, socially, and economically sustainable.

Life Cycle Assessment of reusable plastic containers throughout the fruit and vegetables supply chain, 2024

Elsevier International Journal: website

Authors: Giacomo Lupi (a), Riccardo Accorsi (a), Ilaria Battarra (a), Riccardo Manzini (a)

(a) Department of Industrial Engineering, Alma Mater Studiorum, University of Bologna, Italy

Abstract

In the food packaging industry, waste, resource utilisation, and transport are critical issues that significantly influence the food supply chain footprint. Several studies evaluated the Life Cycle Assessment (LCA) of food packaging systems by comparing alternative materials and sizes, such as plastic, cardboard, and wood. This study illustrates the results of a LCA conducted on a novel reusable plastic container (RPC) for fresh products travelling within a logistic network made of growers, retailers, package manufacturers, and RPC poolers. It is based on an Italian country-wide distribution system of fruit and vegetables. The novel contributions of this research deal with the utilisation of primary data and the development of a multi-scenario analysis considering different packaging solutions, production recipes, and energy mix at the production plant.

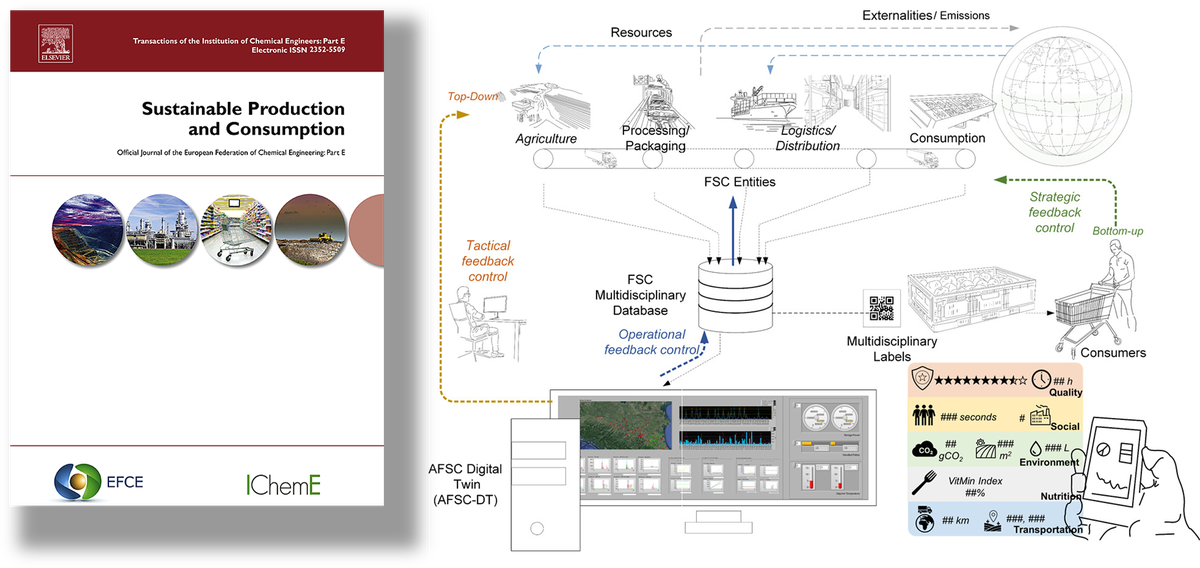

Virtual agri-food supply chains: A holistic digital twin for sustainable food ecosystem design, control and transparency, 2024

Elsevier International Journal: website

Authors: Beatrice Guidani (a), Michele Ronzoni (a), Riccardo Accorsi (a,b)

(a) Department of Industrial Engineering, Alma Mater Studiorum - University of Bologna, Viale del Risorgimento 2, Bologna, 40136, Italy

(b) CIRI –AGRO, Interdepartmental Center for Industrial Research of the University of Bologna, Via Quinto Bucci 336, 47521 Cesena, FC, Italy

Abstract

The transition of Agri-Food Supply Chains (AFSC) toward sustainable patterns able to secure safe, quality, and affordable food whilst preserving natural and anthropogenic ecosystems is a key challenge of this century. Increasing production and distribution operations' transparency and impact visibility uncovers hidden complexities and the food ecosystem's externalities. To this attempt, this paper introduces a novel Agri-Food Supply Chain digital twin (AFSC-DT) able to virtualize the agricultural, processing, warehousing, and distribution operations holistically from-field-to-consumer and estimate economic, logistic, environmental, safety, and nutritional indicators associated with any food order, assumed as the functional unit. The AFSC-DT behaves as a control tower, providing a multi-dimensional dashboard of indicators and labels to enhance practitioners' and consumers' knowledge of FSC entities and operations. The practitioner's visibility drives top-down operational and tactical feedback controls through real-time monitoring and a-posteriori multi-dimensional performance analysis, whilst consumers, with their informed choices, perform a strategic bottom-up pressure on the food industry toward a sustainable redesign. A what-if simulation analysis conducted over four virtual scenarios within a regional horticultural AFSC proves how the AFSC-DT aids informed decision-making across the AFSC echelons, stimulating a virtuous cycle and favoring a progressive transition toward more sustainable patterns.

Warehousing and Material Handling Systems for the Digital Industry, 2024

Springer International Publication: website

Editors: Riccardo Manzini (a), Riccardo Accorsi (a)

(a) Department of Industrial Engineering, Alma Mater Studiorum – University of Bologna, Italy

About the book

This book illustrates innovative support-decision models, methods, and advanced automation and robotic technologies aimed at enhancing the overall performance of Warehousing and Material Handling (WMH) in terms of time and space efficiency, service levels, labor safety, and ergonomics. It provides a collection of cutting-edge issues commonly faced in warehousing systems worldwide, along with a structured set of methodologies and technological solutions to address them.

Warehousing and Material Handling (WMH) are pivotal processes within supply chain and production systems. They involve the handling, consolidation, and storage of goods such as raw materials, parts, components, and finished products within distribution centers. WMH is also a key component of distribution networks, serving as a hierarchy of facilities dedicated to receiving materials from vendors and shipping to customers while meeting service level and performance targets.

The book offers readers the opportunity to explore this topic from multiple knowledge levels and perspectives. At the basic level, it introduces readers to the problems, issues, nomenclature, fundamental models, and methods to support the decision-making process. At an intermediate level, it delves into the state-of-the-art on critical issues in warehousing and material handling systems. Finally, at an advanced level, it delves into the most challenging and recent research and industry issues, addressing both providers and users of WMH solutions and technologies.

The book's intended audience includes undergraduate students, graduate students, PhD students, post-doc researchers, scholars, and researchers from academia and industry. It is also relevant for practitioners and managers working in production, logistics, and supply chain environments. The authors' approach is multidisciplinary, with a special focus on logistics, automation, optimization, safety, ergonomics, and the overall sustainability of WMH systems and operations.

Influence of an innovative, biodegradable active packaging on the quality of sunflower oil and “pesto” sauce during storage, 2023

Elsevier International Journal: website

Authors: Virginia Glicerina (a), Lorenzo Siroli (b), Davide Gottardi (b), Nicole Ticchi (c), Filippo Capelli (d, e), Riccardo Accorsi (d), Matteo Gherardi (e, f), Matteo Minelli (g), Maurizio Fiorini (g), Vincenza Andrisano (c), Vittorio Colombo (e, f), Riccardo Manzini (d), Rosalba Lanciotti (b, h), Santina Romani (b, h)

(a) Department of Agriculture, Forest and Food Sciences, University of Turin, 10095 Grugliasco,TO, Italy

(b) Department of Agricultural and Food Sciences, Alma Mater Studiorum, University of Bologna, 47521, Cesena, FC, Italy

(c) Department for Life Quality Studies, Alma Mater Studiorum – University of Bologna, 47921, Rimini, Italy

(d) Department of Industrial Engineering, Alma Mater Studiorum – University of Bologna, 40136, Bologna, Italy

(e) Advanced Mechanics and Materials, Interdepartmental Center for Industrial Research (AMM-ICIR), University of Bologna, 40123, Bologna, Italy

(f) Department of Industrial Engineering (DIN), University of Bologna, 40123, Bologna, Italy

(g) Department of Civil, Chemical, Environmental and Materials Engineering (DICAM), Alma Mater Studiorum, University of Bologna, 40126, Bologna, Italy

(h) Interdepartmental Centre for Agri-Food Industrial Research, Alma Mater Studiorum, University of Bologna, 47521, Cesena, FC, Italy

Abstract

The aim of this research was to produce an innovative, biodegradable multilayer active packaging solution, with excellent oxygen barrier properties, to extend shelf- life of oily foods. In fact, one of the main drawbacks of biodegradable films is the low barrier they offer against external agents that can thus easily accelerate the foods degradation during shelf-life. In this study, a multilayer material obtained by the adhesion of two polylactic acid (PLA) films with cold plasma application, in place of synthetic adhesives, was realized. Moreover, cold plasma treatment was employed to immobilize the oxygen scavenger agent (ascorbic acid), chosen for the activation of the packaging material. Preliminary studies on activated PLA pouches filled with sunflower oil, used as model system, were performed. Model systems were stored at 35 °C to accelerate oil oxidation phenomenon and analysed for PV and colour during 64 days of storage. After that, different samples of “Genovese pesto”, were tested as real food, stored at 25 and 45 °C and analysed for PV, water activity, rheological parameters and microbiological loads during 41 days of storage. Obtained results showed the greater ability of the new active packaging to decrease the oxidation kinetics of “pesto”, mainly when stored at 25 °C. Moreover, all samples packed in the activated biodegradable pouches (both sunflower oils stored at 35 °C and pesto stored at 25 °C) showed better and more stable quality characteristics, in terms of colorimetric, microbiological and textural parameters when compared with the respective control samples. Overall obtained results highlighted the potentiality of the new biodegradable material, activated with the oxygen scavenger, to be applied successfully in food industry, to extend food products shelf-life and/or maintain high quality levels during storage.

Simulating product-packaging conditions under environmental stresses in a food supply chain cyber-physical twin, 2022

Elsevier International Journal: website

Authors: Riccardo Accorsi (a, b), Marco Bortolini (a), Mauro Gamberi (a), Beatrice Guidani (a), Riccardo Manzini (a), Michele Ronzoni (a)

(a) Department of Industrial Engineering, University of Bologna, Alma Mater Studiorum, Viale Risorgimento, 2, 40136, Bologna, Italy

(b) CIRI – AGRO, Interdepartmental Center for Industrial Food Research, Via Quinto Bucci 336, 47521, Cesena FC, Italy

Abstract

Food supply chains (FSCs) enable safe, effective, and sustainable food distribution, linking farm to table. They involve multiple sources and destinations, a broad set of actors and handling modes, variable and unpredictable environmental conditions, potentially decaying food and packaging, affecting quality and consumer satisfaction. New methodologies, approaches, and ready-to-practice solutions to improve the FSC capacity to maintain the food quality and the packaging properties at the final consumer are expected and missing. To address such aspects simultaneously, this paper proposes a novel framework, using simulation, to study food product and packaging conditions under environmental stresses throughout the FSC. The framework includes five layers of study, i.e., the environmental layer, the FSC layer, the visibility layer, the simulation layer, and the functional layer, linking the field, i.e. the operative physical environment, to a simulation environment, based on a fully equipped and closed-loop controlled physical twin made of a climate-controlled chamber. The cyber-physical twin description is improved by reviewing a collection of case studies we used over the years to validate the framework and explore the functionalities of the physical twin. Case studies deal with different food products and packaging alternatives, demonstrating the flexibility of the proposed framework and physical twin to support the analysis and decision-making in FSC improvement.