SPLASH TEST

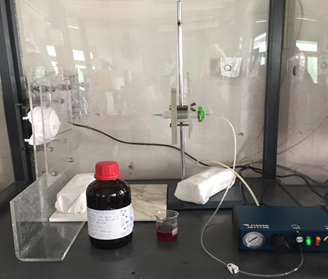

The blood resistance test rig was assembled as indicated by the standard norm. The whole apparatus is shown in the Figure.

In brief, the apparatus is equipped by a specimen-holding frame able to accommodate the whole surgical mask prototype and of a fluid dosing system in which a pneumatic controlled valve is able to dispense a specified volume of blood in a jet stream (Fisnar JB1113N, NJ, United States), using the air activated syringe that is equipped by a cylindrical needle 12.7 mm long and with a 0.83 mm diameter, as requested by the standard norm.

More in detail, the whole frame was fabricated according to the specifications and the quotes indicated in the standard norm, while the mask- holder was produced by 3D-printing.

- Compressed air is used by the instrument to regulate the pressure (double checked by an additional external manometer), while the valve opening time, controlled by the dosing system, allows to control the volume of synthetic blood directed towards the mask surfaces.

- The synthetic blood was prepared according to the following method: 5% w/v of Poly(ethylene glycol)-b-poly(propylene glycol)-b-poly(ethylene glycol) (Pluronic® F-108, Sigma Aldrich, Italy) was added to 1 L of distilled water previously boiled for at least 5 min. The solution was kept under agitation for 1 h and subsequently sonicated for 15 min. 30 g of Rhodamine (purity > 95%, Sigma Life Science USA) was added to the solution with a further agitation for 40-60 min, using an orbital shaker.

-

The surface tension of the synthetic blood was measured three times by the pendant drop method using a Theta Lite tensiometer (Biolin Scientific, Sweden). The solution has a surface tension equal to 41.45 mN/m.

-

Density was measured in triplicate using a 1.0 mL Hamilton syringe and an AX224 Sartorius balance (Lab Instruments GmbH & Co. KG Goettingen Germany) with 0.0001 g precision. The solution has a density of 1015 kg/m3.

-

Before each test the sample iwa preconditioned in a chamber with a relative humidity of (85 ± 5) % at room temperature (21 ± 5) °C and the pressure of the air and the volume of the blood sprayed wwere checked.

-

In a typical analysis, the sample was mounted on the mask-holder and sprayed by 2 mL of synthetic blood jet at a pressure of 16.0 kPa considering a distance from the needle to the mask of (300±10) mm and the center of the specimen as the target area. For each mask prototype, the same test was repeated at least five times considering five different samples.

-

After testing, medial face mask pass/fail determinations were based on simple visual detection of synthetic blood. However, mask samples with particular color, written or design need the addition of talcum powder to rule out the possibility of blood trail.

-

The standard norm imposes an acceptable quality limit (AQL) of 4%, which is defined on a number of samples of 32. Since during the pandemic the number of masks supplied for each type was not enough for the analysis, the 4% was considered on a smaller number of sample but each sample tested had to pass the test to be classified as a IIR mask.