A laboratory where you can experiment, design and realise the first prototype of projects in a multitude of fields and sectors, such as fashion, design, biomedical, engineering, agribusiness, restoration and more.

Makerspace is a laboratory offering customised digital fabrication services in additive and subtractive manufacturing, electronic component development and rapid prototyping, equipped with technologically advanced tools such as 3D printers (FDM, SLA, SLS), laser cutters, CNC milling machines, 3D scanners, etc., capable of flexibly and semi-automatically producing a wide range of objects.

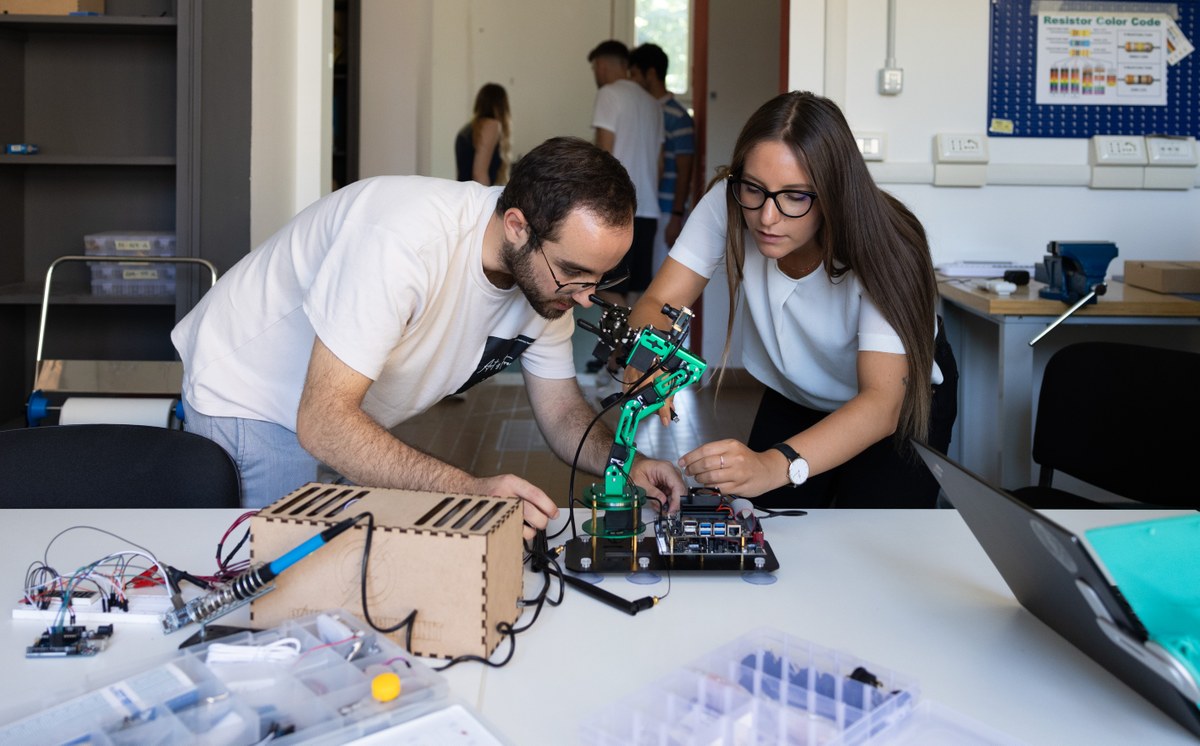

From a design concept or 3D model, the process of formation takes place in various levels of depth, materialising in the actual production of prototypes. The creation of the prototype is a collaborative process, to define the phases in the work and minimise technical problems.

In the section “Calls – The opportunities offered by the University”, search for and select:"Bando Makerspace - Bando per accedere ai servizi di prototipazione del laboratorio Makerspace"

View the prototypes created and come make your idea reality

To use Makerspace equipment, you must take a special safety training course - Unit III Civil Risk.

Reservations can be made up to 12 noon on the day before the training date.

For queries or information, please write to nicola.torcellini@unibo.it

Makerspace – Prototype Laboratory. Viale Carlo Pepoli 3/2, 40123 Bologna. Monday to friday, from 10.00 to 17.00

For any questions or further information, please email us at makerspace@unibo.it