Additive Manufacturing

Different processes for a single purpose

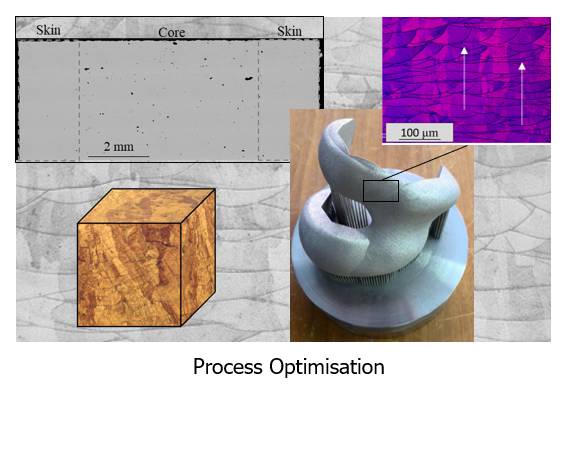

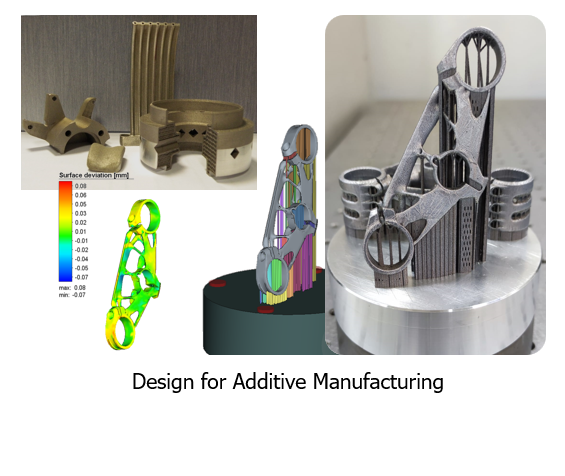

For seven years, the Research Group has been actively involved in the study and optimisation of additive processes for metals, with particular focus on Laser-powder bed fusion (LPBF) and Direct Energy Deposition (DED) processes. Thanks to the use of commercial equipment and collaborations with companies and other research centres, the study of components obtained by additive processes has led to the publication of several papers in leading international journals.

The topics of interest cover different sectors, from bio-medical to automotive, which require excellent knowledge of the process for very different metal alloys that has been successfully developed over the years. In addition to process optimisation, the research group has a good command of software that supports the work in the design and production phases. From 2021, a PhD in wire-arc additive manufacturing (WAAM) process development has been in place.

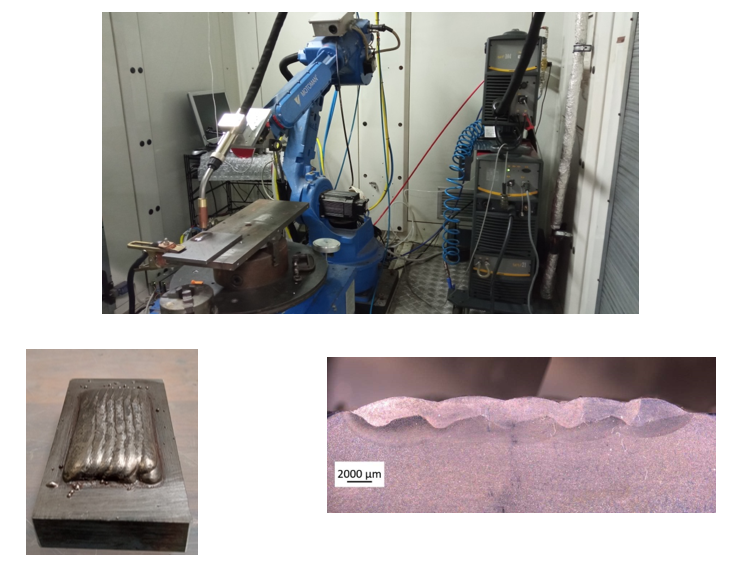

The wire-arc additive manufacturing (WAAM) technology involves melting a metal wire to form three-dimensional parts according to predefined paths using an electric arc as a heat source.

WAAM technology has wide-ranging applications in many manufacturing sectors. Over the last five years, scientific production has increased rapidly.