Nearly 40% of chemical energy of food ends up in wastes or in wastewaters. Wastewater organics are concentrated through aerobic wastewater treatment plant (WWT) yielding biosolids with an overall European production equal to 20 Mton/y in the EU area (Eurostat, 2017).

As wastewater treatment improved, sludge production increased. Regulations moved the practice from open disposal on land and oceans, to bans on ocean dumping, and beneficial land-based reuse.

WWT sludge is actually disposed through land application (56%), incineration (27%) or landfilling (17%), with greenhouse gas emissions, potential biohazard and variable disposal cost between 5 and 120 € per wet ton. Today more than ever, there is the need of reducing sludge and its chemical and energy content exploitation, converting sludge from a cost to a benefit.

Existing commercial solutions cannot treat all types of sludge and suffers from relative high fixed costs that are poorly mitigated by a relatively low value of the final product. On the other hand, there is a large demand for renewable biodegradable materials (e.g. bioplastics) to reduce fossil fuel consumption and plastic waste pollution.

Worldwide plastic production is growing every year and now exceeds 400 Mtons/y. Around 6% of produced plastic ends up in natural environment and oceans where currently float more than 269 million tons of plastic!

To stop plastic accumulation in the environment, is time to improve waste management, in order to remove plastic from the environment and to switch to an intrinsically safe alternative: biodegradable plastics!

Biodegradable plastics have the same properties as conventional ones but can offer the additional advantage of creating no waste and reducing carbon footprint when they are bio-based.

However, traditional non‐biodegradable fossil‐based plastic are cheap (< 2 €/kg) whereas up to now biodegradable plastic costs up to 6 €/kg. Hence, the cost of shifting to this new material can be unacceptable for poor countries. These countries are actually the hotspots of uncontrolled release of plastic waste and any change that would not involve them will be just ineffective for the goal.

To help the environment, biodegradable plastics must become cheaper and used everywhere!

There is only one solution to obtain cheaper biodegradable plastics and to reduce sludge disposal at the same time: using a feedstock without value (wastes) and develop robust, simple and safe production processes.

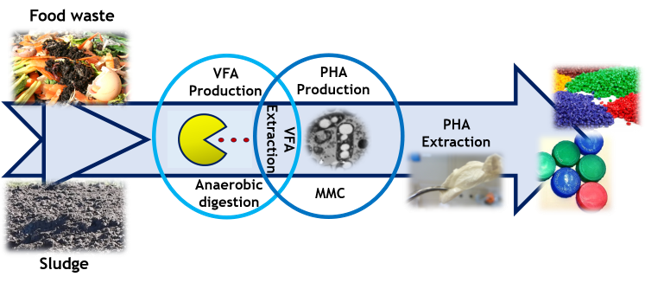

The B‐PLAS project aims to realize fully automated plant that allows to convert food waste, waste sludge and other organic residues into Polyhydroxyalkanoates (PHA).

PHA is a bio‐based and bio‐degradable plastic, suitable for packaging, disposable items, medical application and 3D printing.

Currently the cheapest bioplastic spool costs more than 30 € per kg, bioplastic pellets more than 6 € per kg, food and other organic wastes are readily available and free.

B‐PLAS process could be applied wherever organic waste and sludges are available.

On a world basis, 1‐2 billion ton of food waste and 1‐1.5 billion ton wastewater treatment sludge is produced yearly. The processing of that material would decrease waste generation within a win/win solution that generates a bioplastic production by more than 55 Mton of PHA and 300 Mton of high‐quality compost as byproduct.

B‐PLAS aims to provide a renewable source of material, and to trigger on a new de‐localized industry which can benefit the environment and people, bringing jobs, new knowledge and welfare in a virtuous cycle. The open source strategy is the hallmark of our idea, and will open this business to several creative people, which could modify the equipment and provide new knowledge, hence everyone will benefit.

This will further improve the process and provide more opportunities for the people that will join us in this adventure.