B-PLAS DEMO is constituted by 4 interacting work packages

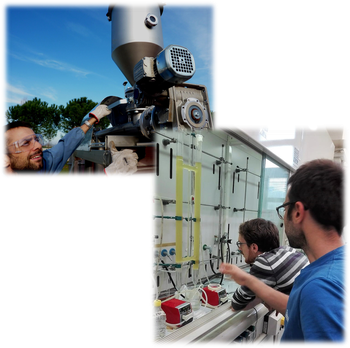

WP1 is dedicated to the construction/start-up and stable operation of the B-PLAS DEMO plant able to continuously produce PHA with acceptable purity

The plant is formed by several sections:

WP2 is focused on the characterization of polyhydroxyalkanoates (PHA) produced by the B-PLAS plant, particularly:

WP3 is dedicated to the design of a cost-effective 10,000 ton/y plant

The plant has to be able to be replicated and to demonstrate its economic feasibility in an specific defined business case

WP4 will bring the B-PLAS technology to the market by means of three main interrelated activities: