Experimental studies on Wire-and-Arc Additive Manufacturing (WAAM)

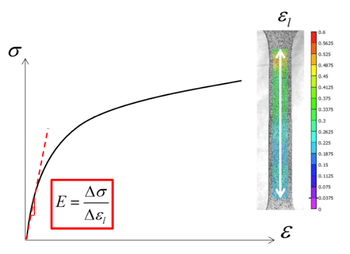

Material characterization of WAAM metals

The research is devoted to fully characterize metal parts realized with Wire-and-Arc Additive Manufacturing (WAAM). Mechanical tests and microstructural evaluations are performed to fully understand the behavior of several WAAM alloys, including stainless steel, structural steel, alluminium.

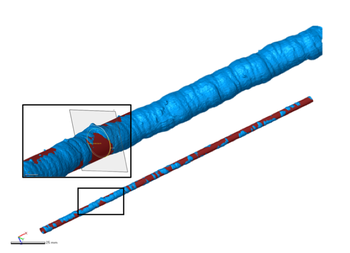

Geometrical characterization of WAAM elements

The research is devoted to fully characterize the geometrical properties metal parts realized with Wire-and-Arc Additive Manufacturing (WAAM) integrating different types of measurements and tests including 3D laser canning, tomography,..

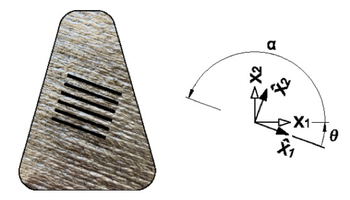

Constitutive models for WAAM materials

The research is devoted to formulate ad-hoc constitutive models for a WAAM-processed metals, considering the typical orthogonally anisotropic (or orthotropic) constitutive law, with parameters calibrated through experimental results.

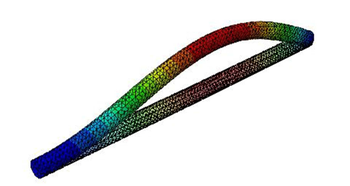

Digital twin studies on WAAM elements

The research investigates the influence of the geometrical and mechanical features of WAAM dot-by-dot elements through the definition of "digital twin" models. Such models are able to replicate all geometrical imperfections and variations of the mechanical properties to predict the structural response of WAAM bars.