Geometrical characterization of WAAM elements

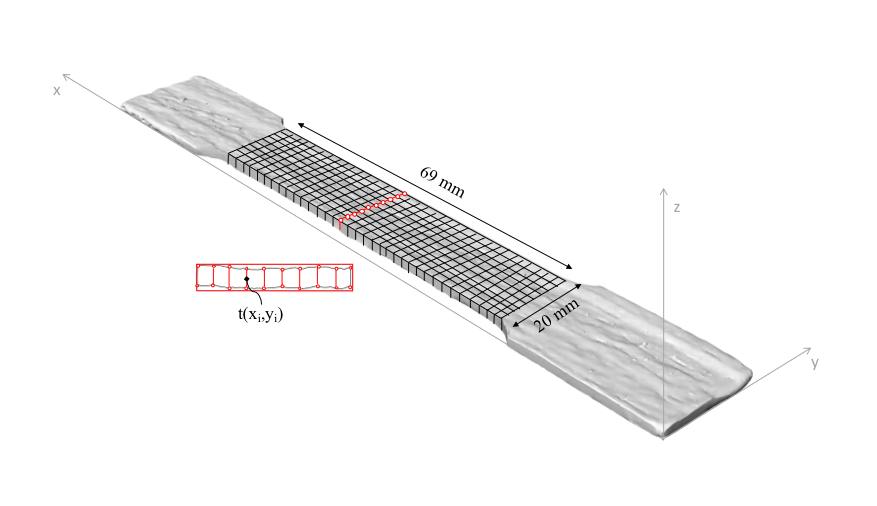

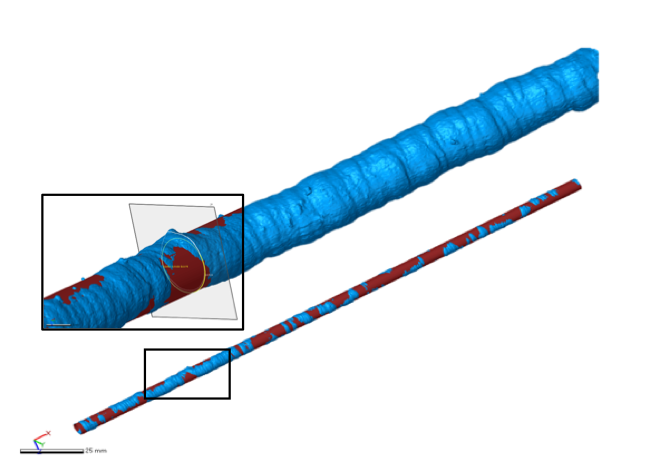

With the aim of assessing the geometrical features proper of WAAM process, ad-hoc geometrical characterization has been carried out on two types of specimens: (i) dog-bone specimens cut from plates printed with layer-by-layer continuous strategy and (ii) bars printed with dot-by-dot strategy.

For both types of specimens, the geometrical characterization has been carried out in two steps. First, detailed investigation on the inherent geometrical irregularities in terms of surface roughness and thickness variation has been analyzed through 3D scanner of one planar specimen. Then, general information on the effective cross-sectional area of the planar specimens tested has been performed through manual and volume measurements.

The results were then used to estimate the key effective mechanical properties of WAAM as-built specimens.

References

Laghi, V., Palermo, M., Gasparini, G., Girelli, V. A., & Trombetti, T. (2021). On the influence of the geometrical irregularities in the mechanical response of Wire-and-Arc Additively Manufactured planar elements. Journal of Constructional Steel Research, 178, 106490.

Laghi, V., Palermo, M., Tonelli, L., Gasparini, G., Girelli, V. A., Ceschini, L., & Trombetti, T. (2022). Mechanical response of dot-by-dot wire-and-arc additively manufactured 304L stainless steel bars under tensile loading. Construction and Building Materials, 318, 125925.