THE GREEN HYDROGEN LAB

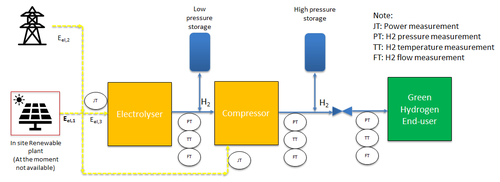

Process Flow Diagram of the plant

The Green Hydrogen Lab is the laboratory of the UNIBO research team, which aims to characterize the performance (Key Performance Indicators) of the components installed in Power to Gas plants.

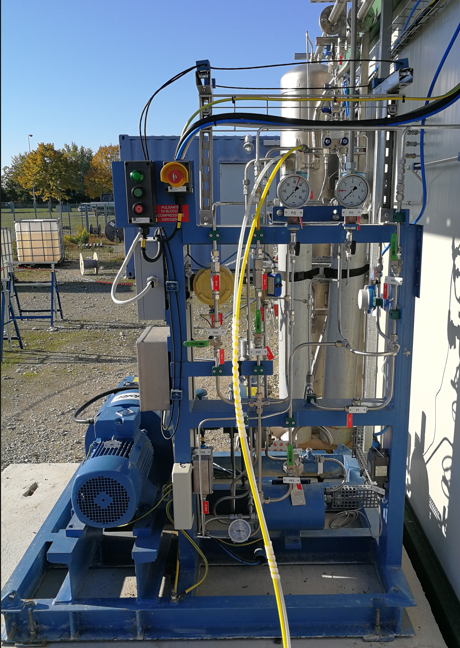

Thanks to a "plug and play" design, the system is easily movable, thus avoiding lengthy and costly installation activities. Furthermore, it can be installed outdoors, thus simplifying all activities relating to safety aspects.

The plant is currently powered by a 1 Nm3/h alkaline electrolyzer, downstream of which filters are installed to achieve the level of purity required for subsequent uses. A volumetric membrane compressor is installed downstream of the compressor, compressing the hydrogen produced from 2.5 to 35 bar. Finally, the hydrogen is stored at a maximum pressure of 35 bar inside an 83-liter tank if production exceeds demand.

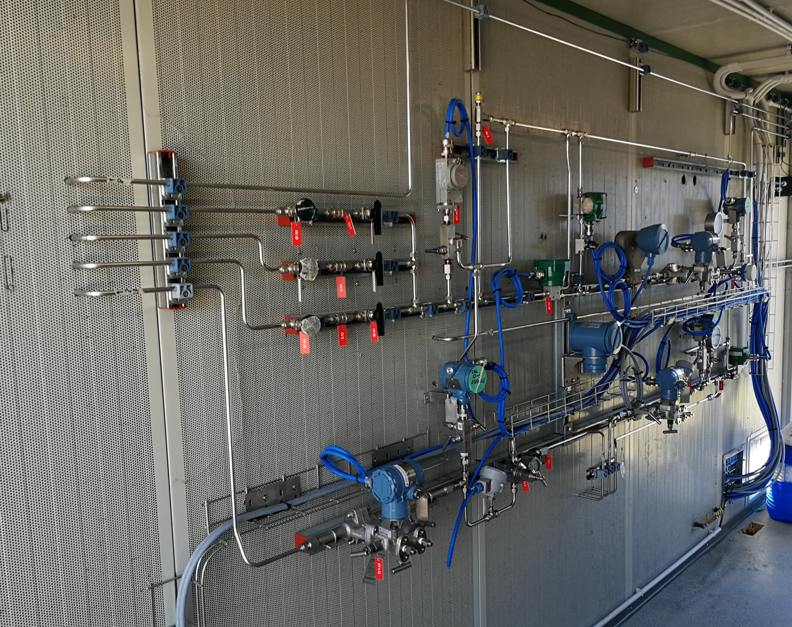

The process parameters are constantly monitored and acquired by the instrumentation positioned in line (temperature, pressure, and flow rate transducers). The signals are sent to the data acquisition and processing system in a safe area. The operator analyzes the trends and implements the operations required for the exercise.

To facilitate installation and possible movement, the laboratory has been created inside two "plug&play" cabinets: the "process" cabinet and the "data acquisition" cabinet.

- All process operations are confined to the "process" cabinet, i.e., where flammable and explosive substances could be emitted. To this end, all the equipment installed is ATEX certified. Inside, there are dedicated devices for detecting the presence of hydrogen.

- In the "data acquisition" cabinet, indicated as a "safe area," the electrical panels, the PLC, and all those elements necessary for the control, regulation of the process, and data acquisition are located.

Album