RESEARCH PROJECT

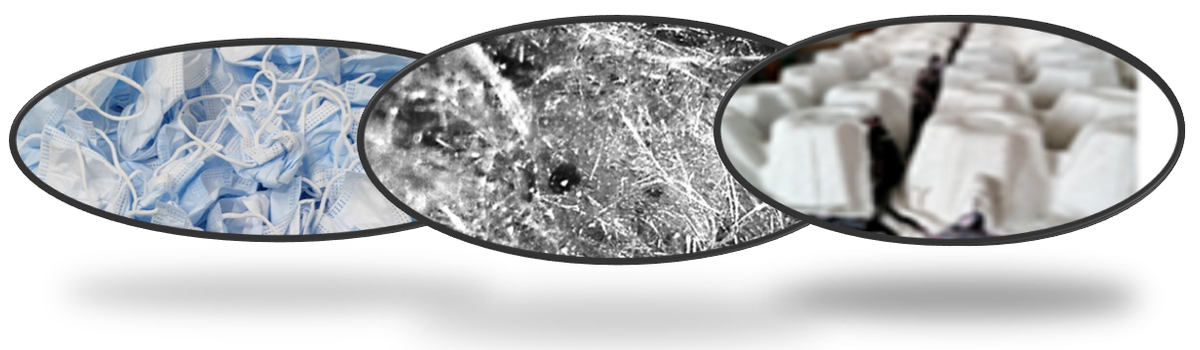

The aim of the research project is the design and identification of low-cost, safe, easy to be composed and installed panels to improve the building indoor thermal and acoustic quality in disadvantaged contexts, where people cannot afford commercial materials. These panels should be similar to commercial solutions but they are made of end-of-life household materials (EoLHM), such as clothes and packaging made of cardboard, glass, plastic or metal; indeed, given that EoLHM are cheap and available almost anywhere, they are suitable to become low-cost improvements in thermal and acoustic indoor comfort conditions for people living under the poverty threshold.

Keywords: environmental comfort; sustainability; meatmaterials; reuse; circular economy; social housing.

This research is founded by Italian Ministry of University and Research (MUR), Grant number: 2022MW3CSK.

The research units involved in this project are the University of Bologna (Coordinator), the University of Parma, the University of Trieste, and the University of Brescia.

The design of the panel made of EoLHM materials consists in identifying the sequence and thickness of the layers that guarantee a low value of the thermal transmittance, a periodic thermal transmittance suitable to the context, and that avoids vapor condensation in the panel. At the same time, the identified layers sequence guarantees sound absorption and insulation. For improving the sound absorption performance, superficial finishing may be identified such as the perforation of the panel but this will be defined by considering also other aspects such as the fire resistance of the panel.

The definition of the panel layers sequence is done by a MATLAB code. By entering the characteristics of the building envelope to be refurbished, the performance to be reached according to the standards, and by creating a database that collects all the properties determined for the selected EoLHM, the code will propose a stratigraphy of the panel. The proposed panel stratigraphy will be used to perform numerical simulations with COMSOL Multiphysics and Energy+ to assess the influence of the panel on the building indoor conditions. COMSOL Multiphysics is available at UniBS and it is suitable to analyze heat fluxes and temperature distribution in the panel, while Energy+ is an open-source software suitable to analyze the thermal performance of a dwelling. COMSOL is also used at UniPR for performing acoustical calculations. Simultaneously, a full-scale experimental campaign will be performed on the final version of the panels. Samples will be realized and tested thermally, acoustically and also for the fire resistance part. As regards the fire resistance tests, it will be identified how to improve the fire resistance of the panel. At this stage, surface treatments and other features to improve the panels appearance and performance are identified. Finally, the final version of the panel is realized and tested in-situ. In-situ tests are necessary to verify the metamaterials performances from the thermal point of view but especially from the acoustic point of view. For this kind of tests, special sound sources, a sound intensity apparatus and an Acoustic Camera system will be used. The tests will be performed mainly by using acoustic holography and sound intensity probes, as these methods provide “acoustical images” which identify local anomalies and acoustical weak points.