The Project

The MicroEmiRo project aims to improve the quality and safety of food productions in the Emilia-Romagna Region through the exploitation of selected microbial cultures. The MicroEmiRo research team is skilled in preparation of raw materials, optimisation of fermentation processes, taste and aroma valorization, food safety, and best possible conditions for product processing and preservation.

MicroEmiRo contribution to food safety: check out the BC Centre for Disease Control Guidelines on nut cheese fermentation food risk assessment

STATE O F THE ART

The use of microorganisms to preserve food dates back to ancient times, even if fermentation processes were performed under empiric and domestic conditions. In the last decades, the continuous study of complex microbial consortia responsible for the wide variety of fermented products allowed the isolation of thousands of bacterial and fungal strains. Nowadays fermented products play an important economic and cultural role at regional, national and international level. This precious heritage of microbial biodiversity can be used to produce new foods or to increase the quality and safety of existing fermented foods.

Exploiting microbial collections

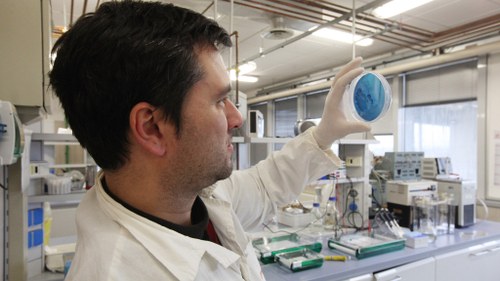

MicroEmiRo valorizes the technological potential and biodiversity of microbial resources located in four laboratories (CIRI Agroalimentare as coordinator, SITEIA.PARMA, BIOGEST-SITEIA, BioDNA) belonging to the High Technology Network of the Emilia-Romagna Region. The partnership also includes five companies (EuroCompany, Clai, Macè, Caseificio Mambelli, Chr Hansen) specialized in different food productions.

Objectives

MicroEmiRo’s principal purpose is the optimization of technological performances, also at industrial level, of selected cultures (mainly lactic acid bacteria) to increase the innovation and competitiveness of the agri-food industry. The project is divided in the following four specific goals, each one of them corresponding to a product:

- development of new nut-based fermented products for vegan consumers endowed with good sensorial properties;

- production of short ripened cheese with low salt, lactose content and calorie intake using starter cultures characterized by specific abilities (aroma profile, exopolysaccharides and bacteriocin production);

- optimization of autochthonous starter cultures to increase sensorial features, safety and recognizability of traditional fermented sausages;

- use of bacteriocin-producing lactic acid bacteria to increase shelf-life and safety of fresh products.

Results

The collaboration between CIRI Agroalimentare and Eurocompany led to the release of a fermented product for vegan consumers on the market in 2017. Workning under an industry-driven European Regional Development Fund (ERDF) project, the MicroEmiRo know-how has been translated into an innovative product. Find out more on Eurocompany's website.

How it is made

Equal amounts of cashews and almonds are weighed out and soaked in a special container with water and lactic bacteria for around ten hours. After the soaking stage, carefully measured amounts of water and salt are added and the product is ground up. The mixture is then left to ferment in a temperature-controlled environment until the pH reaches the right level. Then it is pressed into a mould and dried for 24 hours. Once the drying phase is complete, the product is placed in a seasoning chamber for around five days, until the desired degree of dryness is reached.