The Long Pipe

Overview

The Long Pipe is a closed-loop wind tunnel operating with air at atmospheric pressure. The The reason behind the choice of a closed loop is the possibility to accurately control the flow characteristics, in terms of velocity, temperature and humidity. The various aerodynamics components are the same as those of an ordinary wind tunnel (corners, screens, contraction), inspired by the design of the best existing ones (e.g. MTL of KTH Stockholm). The main difference of the Long Pipe to a typical closed loop wind tunnel is the long test section, which gives most of the friction losses.

The test section

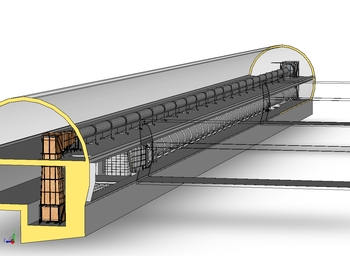

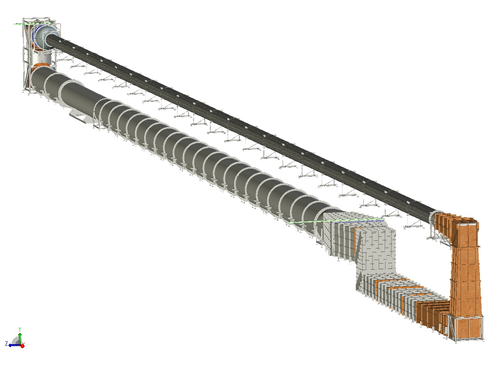

The Long Pipe is the main part of the set up, consisting of a 111.5m tube with an inner diameter of 0.9m. The pipe is made of 22 modular elements, each 5 metres long, plus a 1.5m long module, held on concrete blocks by precision positioning elements to guarantee accurate alignment. Each module, built with extreme care to have the required smooth surface, is made of carbon fibre with flanges at both ends for precise junction of the elements. Furthermore, it has 4 access holes of 15 cm diameter at the downstream end to introduce measurement devices, such as various traversing systems for different sensor types, or gain optical access along the whole length of the pipe (PIV or LDA). The pressure can be equalised anywhere along the pipe length and at the pipe inlet flow manipulators can be in-stalled. The main test section is the 1.5m module, located at the end of the pipe: it can be easily re-moved and can be replaced by a custom made to meet the specific requirements of the experiment to perform. This flexibility allows to use the facility to study several particular flows, such as the effect of non-smooth walls, non-isothermal conditions, the evolution of various non-equilibrium flows, flows with particulates, without the re-design of the entire pipe.

Total length 120 m

Pipe length 111.5 m

Diameter 0.9 m +/- 0.1 mm

Inner surface roughness <0.21 μm

Max speed 60 m/s

Fan power 380 kW

Temperature variation < +/- 0.1 °C

Reynolds number range

High Reynolds numbers are critically important in order to shed light on the general nature of turbulence flow physics, which are ubiqutous in numerous practical engineering situations such as aeronautics, naval applications and energy conversion processes, as well as in many geophysical situations. Turbulence dynamics at high Reynolds numbers are important in neutral and stratified atmospheric boundary layers, and it also plays a crucial role in mixing and dilution of pollutants, and in aspects of climate modelling.

The definition of Reynolds number as Re=UL/ν, shows that there are different possibilities to achieve high Reynolds numbers regime. One option might be increasing the velocity U, not to such high levels that compressibility effects have to be taken into account. It is possible to act on the density, pressurising the air flow facility for instance, or, increase the physical dimension L could be made large. Furthermore, in turbulence studies it is important to have a facility where the spatial size of the smallest scales (viscous length scales, l*) is large enough to be resolvable by the available measurements techinuqes. In a pipe flow, in order to mantain both the Reynolds and the scales large, the physical size of the facility, namely the diameter, should be as extensive as possible. The choice of the pipe flow over other canonical flow, such as the channel or the boundary layer, is due to the advantage it offers in measuring the wall shear stress. In fact, it can be derived directly from the pressure drop along the pipe, which can be measured accurately.

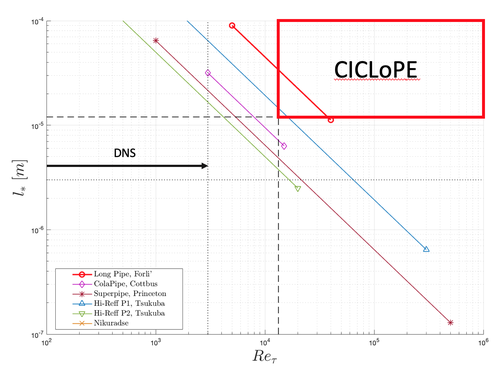

Over the years, numerous pipe flow experiments have been witnessed, although most of them were performed at Reynolds numbers not high enough to observe a clear scale separation. On the other hand, the Princeton Superpipe allows to achieve extremely high Reynolds numbers for a laboratory experiment, at the expenses of very small viscous scales, i.e. for R+=R/l* =500000 the viscous length l* is only slightly above 0.1 mm. In the figure below, the operative range of CICLoPE (the green line in the figure below) is shown together with other pipe flow experiments and facilities. Although it doesn't cover a range of Reynolds as wide as the Superpipe, it is designed such that the scales within that range will be large enough to be reasonably well resolved by present measurement techniques, covering an unexplored region of this parameter space. It is possible to observe how the the Long Pipe in CICLoPE keeps the viscous units well above the 10 µm threshold all across its operative range. Therefore, standard hot-wire probes can be used to acquire turbulent statistcis with no need of a posteriori corrections.