Orthotropic elastic model for WAAM stainless steel

Wire-and-Arc Additively Manufactured (WAAM) stainless steel is characterized by specific mechanical properties which can largely differ from those of traditionally-manufactured material. In particular, according to the microstructural and mechanical characterization, a non-negligible anisotropic behavior appeared to govern the elastic response of the 3D-printed material.

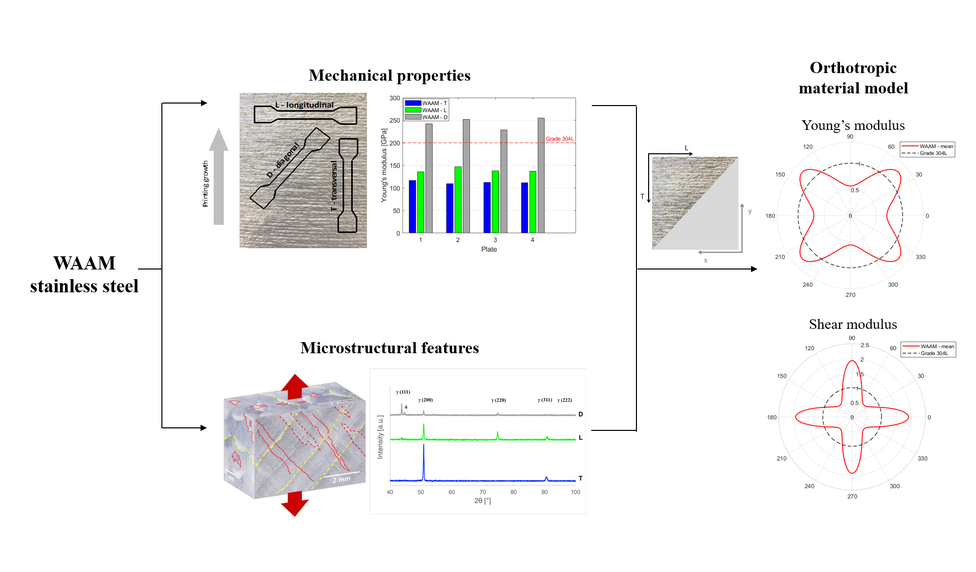

The present work formulates an orthotropic elastic model for WAAM-produced 304L austenitic stainless steel plates based on the results of the experimental tensile tests performed on specimens with different orientations with respect to the printing direction. In detail, Young’s modulus and Poisson’s ratio values were evaluated for samples oriented along three different orientations with respect to the printing deposition layers: longitudinally (L), transversally (T) and diagonally (D) to them. Digital Image Correlation (DIC) optical measuring system was used to acquire the full strain fields during the test. Microstructural investigations were carried out to study the inherent microstructure, characterized by a distinctive grain growth direction, and to assess the preferred crystallographic orientations of specimens extracted along the three considered directions. The experimental results provided strong indications on the orthotropic behavior of the material.

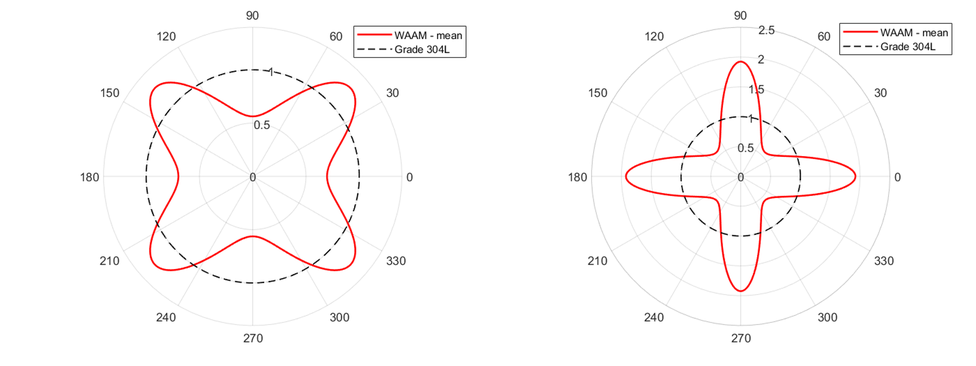

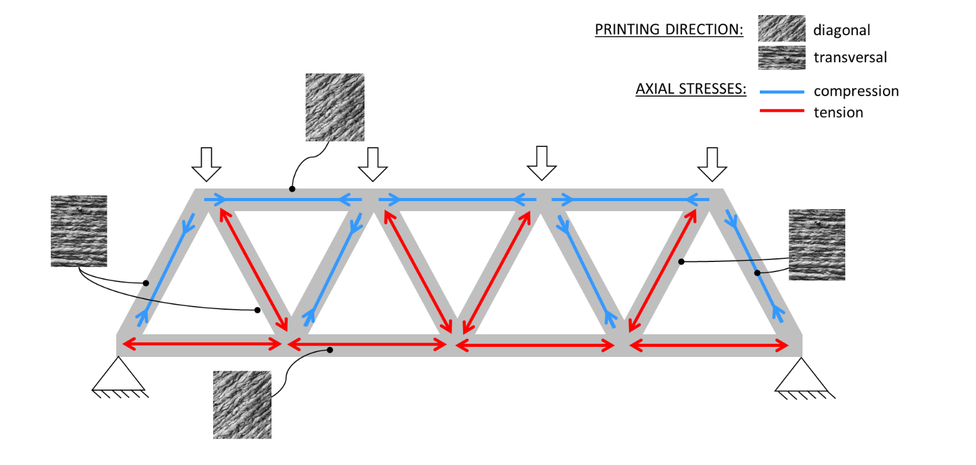

The elastic parameters of the orthotropic material model were calibrated to provide information regarding the full constitutive elastic behavior of the WAAM-produced stainless steel. The calibrated model allowed to derive additional material properties in terms of Young’s and shear modulus along for any printing direction. The resulting values exhibit very large variations with the printing angle with ratios between minimum to maximum values around 2 for the Young’s modulus and 3.5 for the shear modulus. This marked orthotropic behavior could open unexplored design possibilities based on deformability issues. Additionally, the calibrated orthotropic model can be also used for future experimental explorations of the mechanical properties of WAAM-produced steels and for stiffness-based structural design optimizations.

References

Laghi, V., Tonelli, L., Palermo, M., Bruggi, M., Sola, R., Ceschini, L., & Trombetti, T. (2021). Experimentally-validated orthotropic elastic model for wire-and-arc additively manufactured stainless steel. Additive Manufacturing, 42, 101999, https://doi.org/10.1016/j.addma.2021.101999.