Computational design and manufacturing of a diagrid column

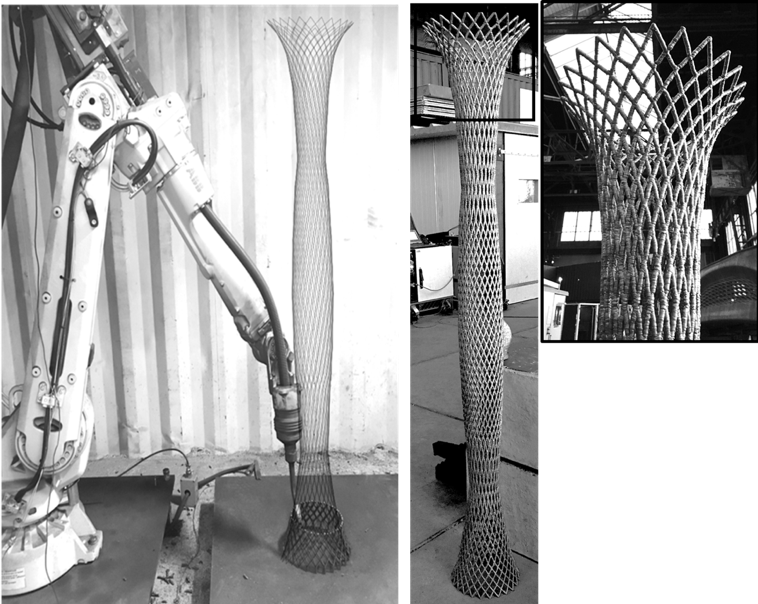

The manufacturing of large scale structures with Additive Manufacturing (AM) represents one of the main challenges facing the construction industry today. The first recent large-scale realizations with the Wire-And-Arc Additive Manufacturing (WAAM) technology have shown the potential of WAAM in changing the way steel structures are currently designed and manufactured. However, despite these pioneering applications, the full comprehension of synergies and possibilities of WAAM in terms of architectural shapes, structural behavior and material response are far from being16completely exploited.

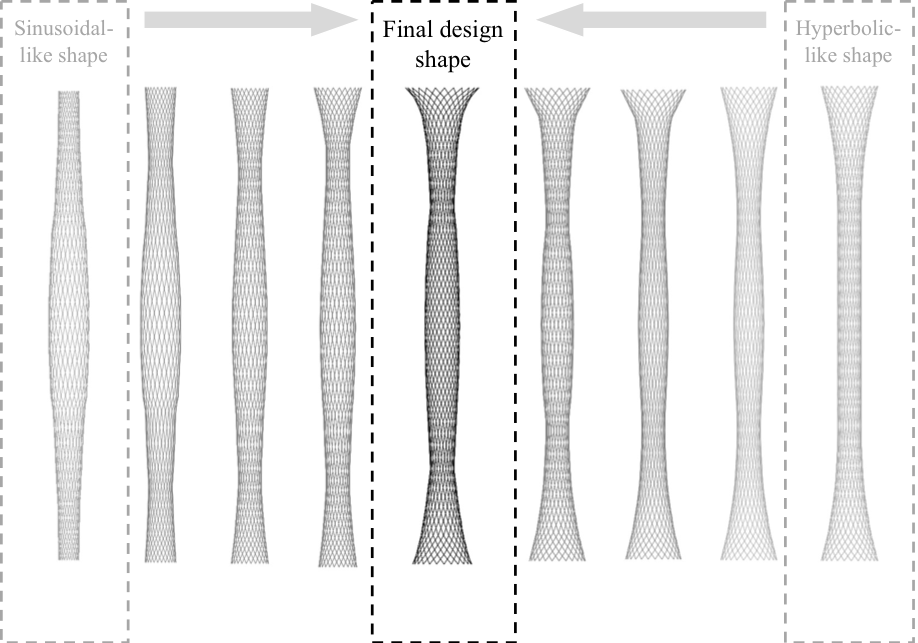

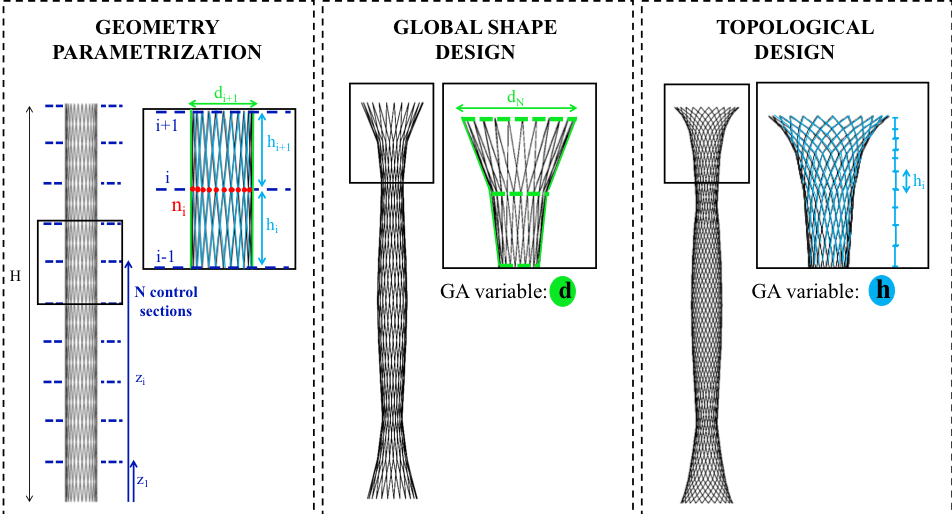

In this research, the overarching design process from concept to fabrication of a half-scaled diagrid column 3D printed with WAAM technology is illustrated. The research methodology is based on a computational workflow integrating various aspects such as material properties, manufacturing features and global architectural design.

The final designed WAAM-produced diagrid column has been exposed at “The Big 5 -International Building and Construction” show, held in Dubai from November 25th till November 28th 2018.

References

Laghi, V., Palermo, M., Gasparini, G., & Trombetti, T. (2020). Computational design and manufacturing of a half-scaled 3D-printed stainless steel diagrid column. Additive Manufacturing, 36, 101505.

Laghi, V., Palermo, M., Gasparini, G., & Trombetti, T. (2019). Optimization studies on diagrid columns realized with Wire-and-Arc Additive Manufacturing process. IABSE Congress 2019, New York City.