The Project

State of the art

A wider use of electric cars for urban personal mobility can be achieved through adoption of market-ready, cheaper vehicles realized by transforming existing used thermal engines cars into renewed full electric cars. This well-known retrofit basic concept has been refined and optimized in terms of technical solutions and implementation methodology by the University of Bologna in the Integrated Technology for Electric Mobility (TIME) research project. Basically, the TIME renewed car is more attractive to potential customers for its lower cost and higher product quality level as compared to other solutions. These results benefit from a massive introduction of circular economy principles together with a more sustainable distributed production system.

The TIME conversion kit

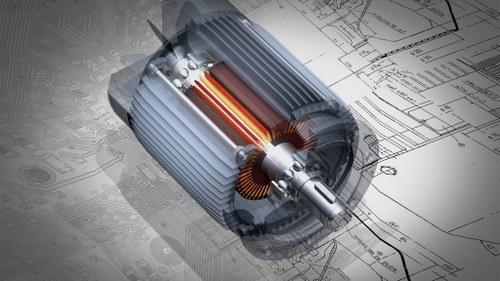

TIME is based on massive application of design for integration concept, in the whole range of components, subsystems and systems of the electric powertrain. In comparison, standard approaches are based on the use of off‐the shelf components requiring a difficult integration activity, having a relevant impact on cost, functionality and system reliability. The TIME conversion kit comes with integrated components sealed in a box. The box, which is fully protected against electric shock, is integrated into the vehicle during the transformation procedure by implementing mainly a mechanical workout. In comparison, standard approaches are based on distribution of electric components around the vehicle, which must be connected one to the other, during the transformation procedure.

Objectives

TIME aims to develop conversion kits designed for used cars conversion to full electric. Combination of industrial activity for kit manufacturing and use of distributed workforce for car transformation represents a new paradigm in the automotive sector and must be based on the involvement of new actors, cooperating on the basis of new economic relations and distribution of technical competences.Therefore, the TIME project pursues four specific goals:

- design and test innovative kit components in all relevant environments;

- develop a multi‐domain design methodology suitable for adapting the conversion kit to different type, size and performance of vehicles;

- define procedures to transform used vehicles and integrate new components;

- release conversion kit and procedures ready for implementation, homologation, testing and demonstration.

Results

The TIME project has designed a conversion kit and transformation procedure that can be applied to cars in EU segment A (mini car) and B (small cars), representing approximately 36% of cars circulating in Europe, and about 45% of cars circulating in large cities. The first available kit resulting from the TIME project is applied to FIAT Panda second generation, produced in 1.3 milion vehicles, most of them still circulating on the road. The TIME conversion kit can be slightly modified to be adapted to more recent cars produced by FIAT group: new FIAT Panda‐third generation (0.85milion in EU) and FIAT 500 (1.6 milion in EU). Production of kits for different car models by other car manufacturers requires engineering work based on TIME project methodology and does not require new R&D activity.

Get in touch

We look forward to answering your requests for information and collaboration ideas.

Please, send your contact request to info@timeforelectric.it

Collaborations of interest include:

- establishing of private partnership to scale up the TIME conversion kit;

- implementation of the transformation centres across Europe;

- large scale diffusion of TIME renewed electric vehicles in European cities.