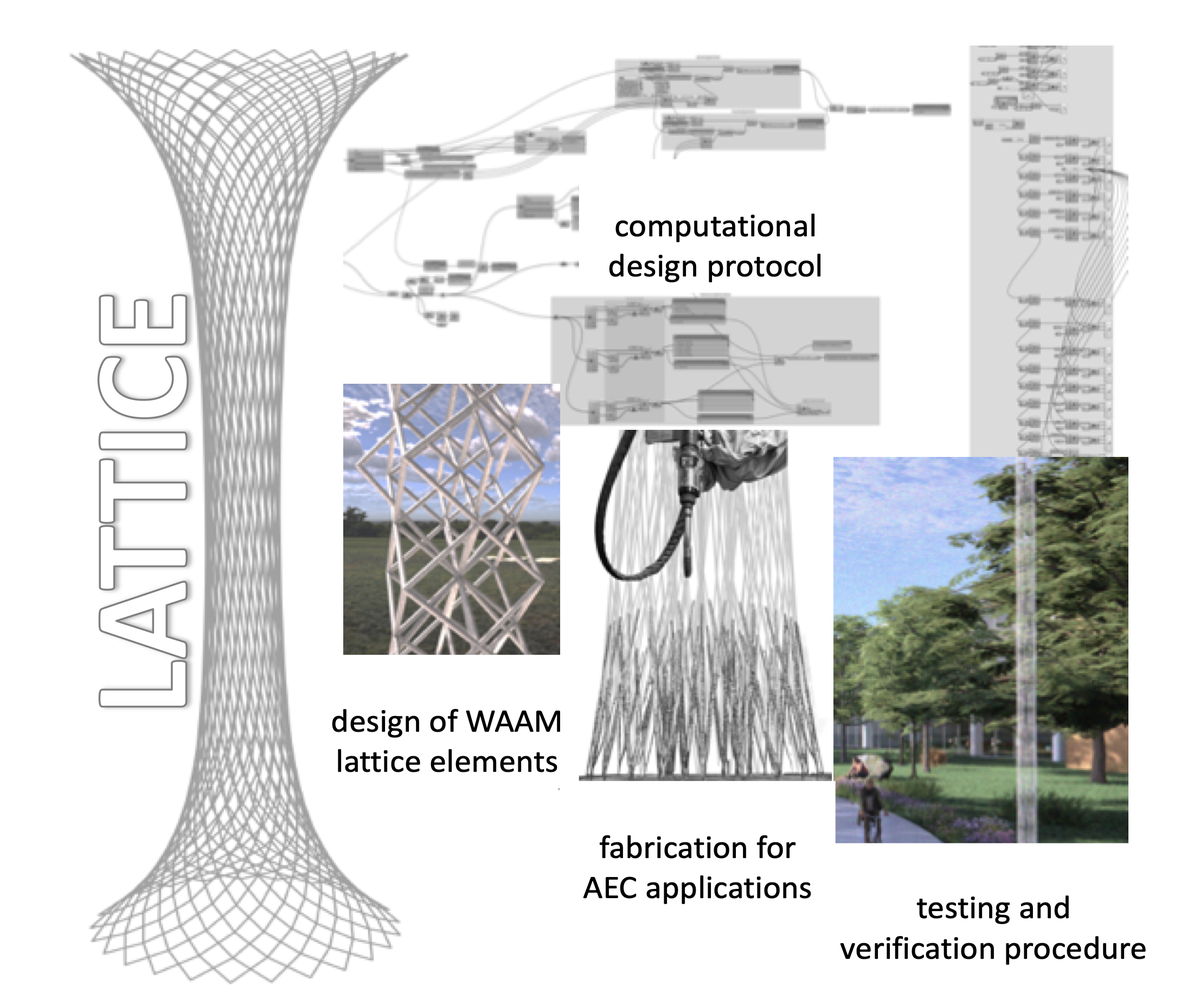

THE PROJECT

The digitalization of the construction sector could potentially produce more efficient structures, reduce material waste and increase work safety. Current strategies for the realization of automated steel constructions see the application of metal 3D printing processes (and in particular Wire-and-Arc Additive Manufacturing) as an opportunity to build a new generation of efficient steel structures with reduced material use. This, though, requires advanced multidisciplinary knowledge in manufacturing, metallurgy, structural engineering and computational design. Lattice structures are characterized by high efficiency (in terms of high stiffness and minimized material use), however their application at the scale of the single element (“meso-scale”), such as beams and columns, is still hampered by the issue of the connection at nodes (in terms of geometry complexity, assembly and production cost). The LATTICE project proposes a comprehensive digital design and fabrication framework for a new generation of steel 3D printed lattice diagrid structural elements for various applications in Architecture, Engineering and Construction. The ambition of the LATTICE project is to propose a new class of efficient structural elements by exploiting the efficiency of lattice structures at the meso-scale through the adoption of WAAM production technology. The increased efficiency of lattice structures is provided by their high structural performances and reduced environmental impact, through the adoption of digital fabrication and optimization techniques for construction. The idea comes from the preliminary result recently awarded with the “Special Mention by Autodesk” at the 3DPioneers Challenge 2021 and a further development in terms of a patent for the realization of efficient lattice geometries. The project activities will contribute to increase the application of 3D printing in construction, with the aim of creating a new generation of metal 3D-printed efficient structures.