KIBO - Advanced kinetic modelling of chemical processes

Experimental and numerical analysis of catalytic and non-catalytic chemical processes (hydrogenation, partial oxidation, pyrolysis, combustion, oxygen-enriched combustion) involving gas, solid and liquid substances

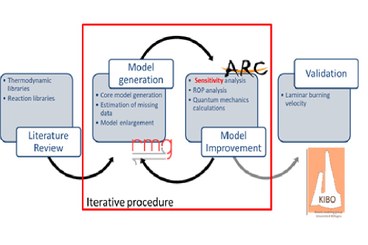

Typically, chemical reactors represent the core of an industrial process. Hence, the accurate evaluation of chemical and physical phenomena occurring within the reactors under operative conditions is an essential step. Indeed, proper control of chemical phenomena (e.g. side reactions) can lead to beneficial effects also on existing processes. Besides, the availability of a validated and advanced kinetic mechanism, such as KIBO, is paramount for the development of innovative solutions on an industrial scale. KIBO is a detailed kinetic mechanism produced by the research group at the University of Bologna, which undergoes a continuous process of improvement, refinement, testing, and validation.

The research activities carried out in this research area are aimed at:

- The realization of a theoretical-based kinetic mechanism suitable for accurate evaluations of chemical and physical aspects determining the overall reactivity of complex mixtures under a wide range of conditions

- The determination of thermochemical behaviour of materials exposed to extreme conditions, including fires, in terms of the mass burning rate of solid, liquid, and gaseous species

- The characterization of the performances of simplified reactors in terms of quantification of temperature and mass profile distribution, identification and characterization of undesired reactions and reaction pathways

- The integration of catalytic and non-catalytic chemistry for the accurate identification of the most critical conditions for real reactors, potentially leading to detrimental effects on economic aspects (e.g. loss in productivity or purity) as well as on safety aspects (e.g. runaway reactions)

- The realization of a preliminary assessment on the feasibility of new concepts for energy production and valorization of low-value streams deriving from industrial processes, including the use of alternative oxidant agents like oxygen-enriched air

- The evaluation of the most relevant safety parameters for gaseous species (e.g. flammability limits, auto-ignition temperature, minimum oxygen concentration) under industrial-relevant operative conditions

Research and Industrial projects on this topic address:

- Runaways in catalytic and thermal Gas-Phase reaction systems (Eurokin consortium - SABIC, VDI)