Dry processes for Acid Gas removal from WtE Flue Gas

Modelling of gas-solid reaction processes for the abatement of acid pollutants, from the characterization of fundamental phenomena at lab scale to the optimization of full-scale flue gas cleaning systems

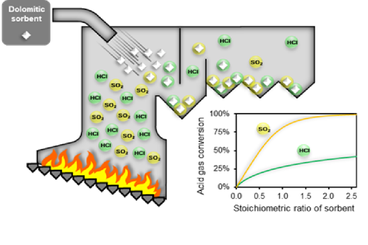

Acid compounds such as sulfur oxides (SO2, SO3) and halogen acids (HCl, HF, HBr) are harmful pollutants for both human health and ecosystem integrity. Their emission is of widespread concern in a variety of combustion processes, ranging from waste-to-energy (WtE) facilities to the glass and ceramics manufacturing industries. Although acid gas treatment has been a conventional component of flue gas cleaning systems for at least a couple of decades, the optimization and intensification of acid gas removal has become a topic of renewed interest in recent years. In accordance with the ambition of the European Union action plan of "zero pollution" for air, water, and soil by 2050, sectoral regulations are setting increasingly stringent acid gas emission standards. Without proper process optimization, current acid gas treatment systems can meet such ambitious standards only with significantly higher reactant feeds, at unsustainable costs and unsustainable rates of generation of process waste. An improved understanding of the reaction processes involved in acid gas abatement is key to couple the compliance with ultra-low emission targets to the achievement of minimal cross-media effects in terms of reactant consumption and generation of process residues.

The research activities carried out in this research area are aimed at:

- the characterization of the reactivity of a wide array of solid sorbents (Ca-, Na-, Mg-based) towards a variety of acid pollutants (SO2, HCl, HF, HBr) in dedicated laboratory setups

- the clarification and quantification of the effect of process conditions (temperature and moisture) on the kinetic and mass transfer phenomena involved in the gas-solid reaction process

- the characterization of synergistic and competitive behaviors in the simultaneous sorption of different acid gases in the flue gas treatment of complex gas mixtures (e.g., WtE flue gas)

- the characterization and optimization of full-scale acid gas removal systems installed in WtE plants or other industrial facilities through historical data analysis and test-run campaigns

- the development of streamlined methodologies for the identification of the optimal acid gas removal configuration (selection of reactants and process conditions) depending on process constraints (flue gas composition, integration with other process units)

- the setup and tuning of advanced control schemes for the operation of full-scale acid gas removal systems, coupling compliance to ultra-low emission standards with the minimization of the streams of reactants and process waste

Research on acid gas removal has been conducted in close collaboration with waste-to-energy companies, flue gas treatment technology suppliers, and local environmental protection agencies.

Research and Industrial projects on this topic address:

- Innovative technologied for flue gas treatment in Waste-to-Energy Facilities (Termomeccanica Ecologia, 2017-2019)

- Optimization of acid gas removal technologies in Waste-to-Energy Facilities (Herambiente, 2016-2023)

- Optimization of multi-stage flue gas treatment processes in Waste-to-Energy Facilities (BEA, 2019-2020)