Laser Welding

A high concentration of energy makes possible welding configurations that are difficult to achieve with traditional technologies.

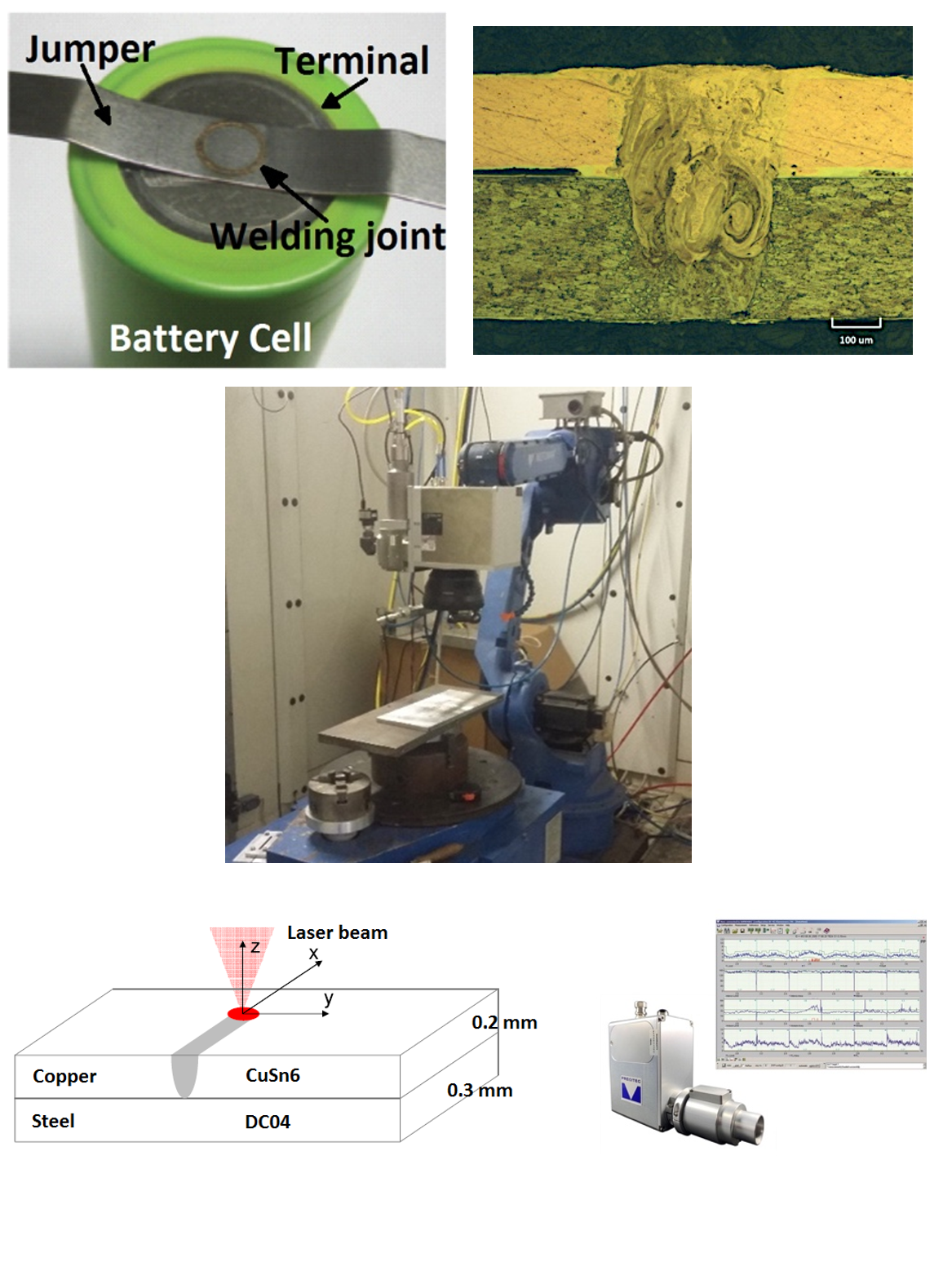

The global trend towards electrification and the green economy is enabling rapid growth in the e-mobility sector. This development has led Laser Group in recent years to actively focus on optimising innovative welding processes for the manufacture of electric car components. Copper and aluminium are the most widely used materials in the industry, and their physical and chemical characteristics and joint configuration make them difficult to weld using traditional processes. In addition, the Laser Group, with the aim of improving the quality of the welding process, integrates monitoring systems to detect defects caused by component tolerances, dirt or different materials.

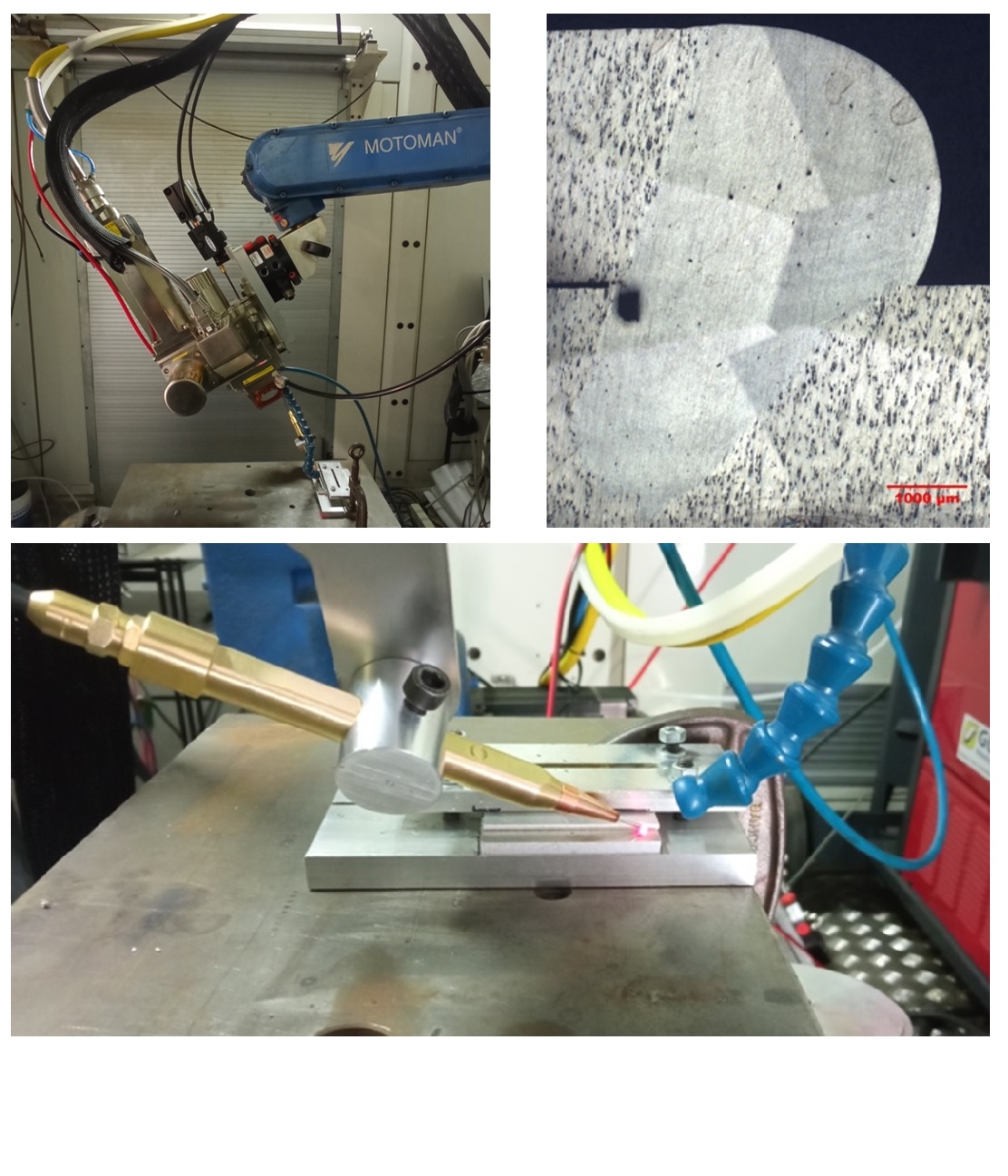

The manufacture of structural elements in electrical machines leads to the need to reduce weight and increase mechanical strength. The common materials used have limitations in terms of weldability. A solution proposed by Laser Group to improve the weldability of structural elements for applications in the e-mobility sector is laser welding with filler material.