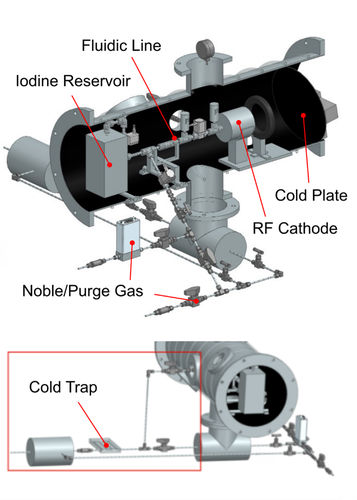

Due to its corrosive nature, iodine requires a special test environment to sustain experiments for a feasible duration. The Institute of Space Systems (IRS), University of Stuttgart (USTUTT), is finalising the concept for a vacuum test facility that will allow characterisation of radio-frequency cathodes operating with iodine propellant. The cylindrical chamber measures 30 cm in diameter and 1 m in length, a scale chosen to accommodate a full cathode plume while still reaching test pressure quickly. The compact volume shortens turnaround times between runs and simplifies iodine handling. It is further equipped with helical thermal control tubing, allowing to heat the chamber walls during the purging phase after an experiment.

Iodine is toxic to the human body in higher doses, hence, the main strategy of operating the facility is that iodine is handled in solid form and shall only be gaseous inside the vacuum chamber. To keep it safely contained, the design relies on a two-stage retention system. A liquid-nitrogen-cooled plate positioned in proximity to the cathode captures most residual vapour before it can enter the exhaust line; any remaining iodine is intercepted by a cold trap placed directly upstream of the forestage vacuum pump. This layered approach prevents corrosive halogens from reaching either the pumping hardware or environment.

During the past months the team has completed the preliminary mechanical and systems design, compiled a comprehensive literature review of existing iodine facilities, including best-practice safety concepts, and carried out a formal hazard assessment that clears the concept for detailed engineering and safety procedures in coordination with both the consortium and the Department of Safety of the University of Stuttgart. Component drawings, procurement and assembly will follow in the next project phase, with the first pump-down and iodine vapour tests planned for late 2025. These milestones position the BOOST team to deliver a versatile and safe platform for Europe’s growing iodine electric-propulsion community.